Support Material In 3d Printing 3d Printing And Fulfillment On Demand Learn how to maximize efficiency and cost effectiveness of your 3d prints by minimizing the need for support materials. we dive into crucial 3d printing topics such as why supports. 3d printers can’t print in mid air without support structures. get to know of 5 types of supports to successfully print designs with overhangs that exceed 45 degrees angle.

3d Printing Truths And Myths Of 3d Printing With Support Material Support materials play a significant role in 3d printing. they make it possible to create complex geometries without significantly affecting the aesthetics of the final printed product. there are a variety of support materials to choose from, each with different advantages. why are support materials important?. 3d printing supports can be done manually with custom supports or automatically by simply enabling supports in your slicer. you can adjust support settings such as support infill, pattern, overhang angle, z distance, and even placement just on build plate or everywhere. not all overhangs need supports. Understanding supports in 3d printing is vital for ensuring successful print outcomes. supports prevent filament extrusion into the air and support overhangs and bridges. they play a pivotal role in maintaining the structural integrity of intricate designs during the printing process. In 3d printing, support structures play a crucial role in ensuring the success of complex prints. these temporary structures provide the necessary backing to a model's overhangs, holes, bridges, or intricate parts, preventing warping, sagging, or complete failure during printing.

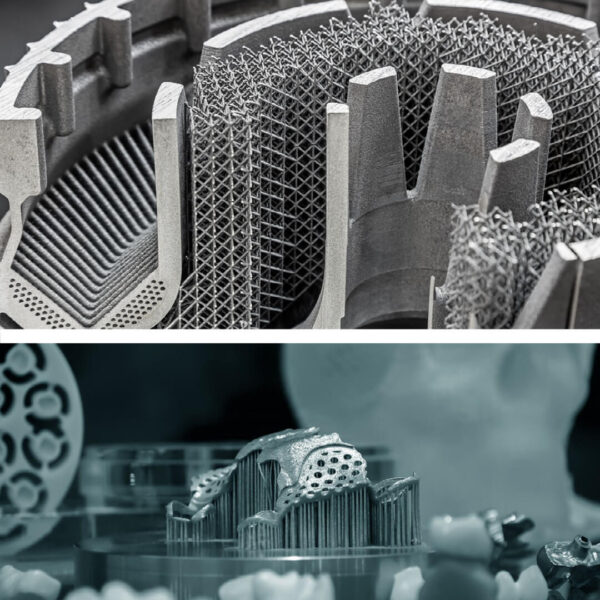

3d Printing Truths And Myths Of 3d Printing With Support Material Understanding supports in 3d printing is vital for ensuring successful print outcomes. supports prevent filament extrusion into the air and support overhangs and bridges. they play a pivotal role in maintaining the structural integrity of intricate designs during the printing process. In 3d printing, support structures play a crucial role in ensuring the success of complex prints. these temporary structures provide the necessary backing to a model's overhangs, holes, bridges, or intricate parts, preventing warping, sagging, or complete failure during printing. Learn how to optimize support structures in 3d printing to enhance model stability, minimize material costs, and maintain model aesthetics. Material for 3d printing. choosing the right material: when choosing support material, ensure it’s compatible with your filament, like pva with pla or hips with abs. consider ease of removal: soluble supports offer clean removal but are pricier, while breakaway supports are more affordable but need careful post processing. What is 3d support material? 3d support material is a low density structure that supports the parts of a model that are prone to failure, such as overhangs. the material is printed in a low density format to ensure it is easily removable from the model when the project is complete. 3d printing supports provide essential scaffolding for complex geometries, ensuring successful fabrication and structural stability during additive manufacturing processes. materials like pla, pva, and composite blends are widely used for supports due to their compatibility, ease of removal, and adaptability to various printing technologies.

Benefits Of Using Support Material When 3d Printing 3d Innovations Learn how to optimize support structures in 3d printing to enhance model stability, minimize material costs, and maintain model aesthetics. Material for 3d printing. choosing the right material: when choosing support material, ensure it’s compatible with your filament, like pva with pla or hips with abs. consider ease of removal: soluble supports offer clean removal but are pricier, while breakaway supports are more affordable but need careful post processing. What is 3d support material? 3d support material is a low density structure that supports the parts of a model that are prone to failure, such as overhangs. the material is printed in a low density format to ensure it is easily removable from the model when the project is complete. 3d printing supports provide essential scaffolding for complex geometries, ensuring successful fabrication and structural stability during additive manufacturing processes. materials like pla, pva, and composite blends are widely used for supports due to their compatibility, ease of removal, and adaptability to various printing technologies.

10 Important 3d Printing Basics You Need To Know Updated Jun 2021 What is 3d support material? 3d support material is a low density structure that supports the parts of a model that are prone to failure, such as overhangs. the material is printed in a low density format to ensure it is easily removable from the model when the project is complete. 3d printing supports provide essential scaffolding for complex geometries, ensuring successful fabrication and structural stability during additive manufacturing processes. materials like pla, pva, and composite blends are widely used for supports due to their compatibility, ease of removal, and adaptability to various printing technologies.