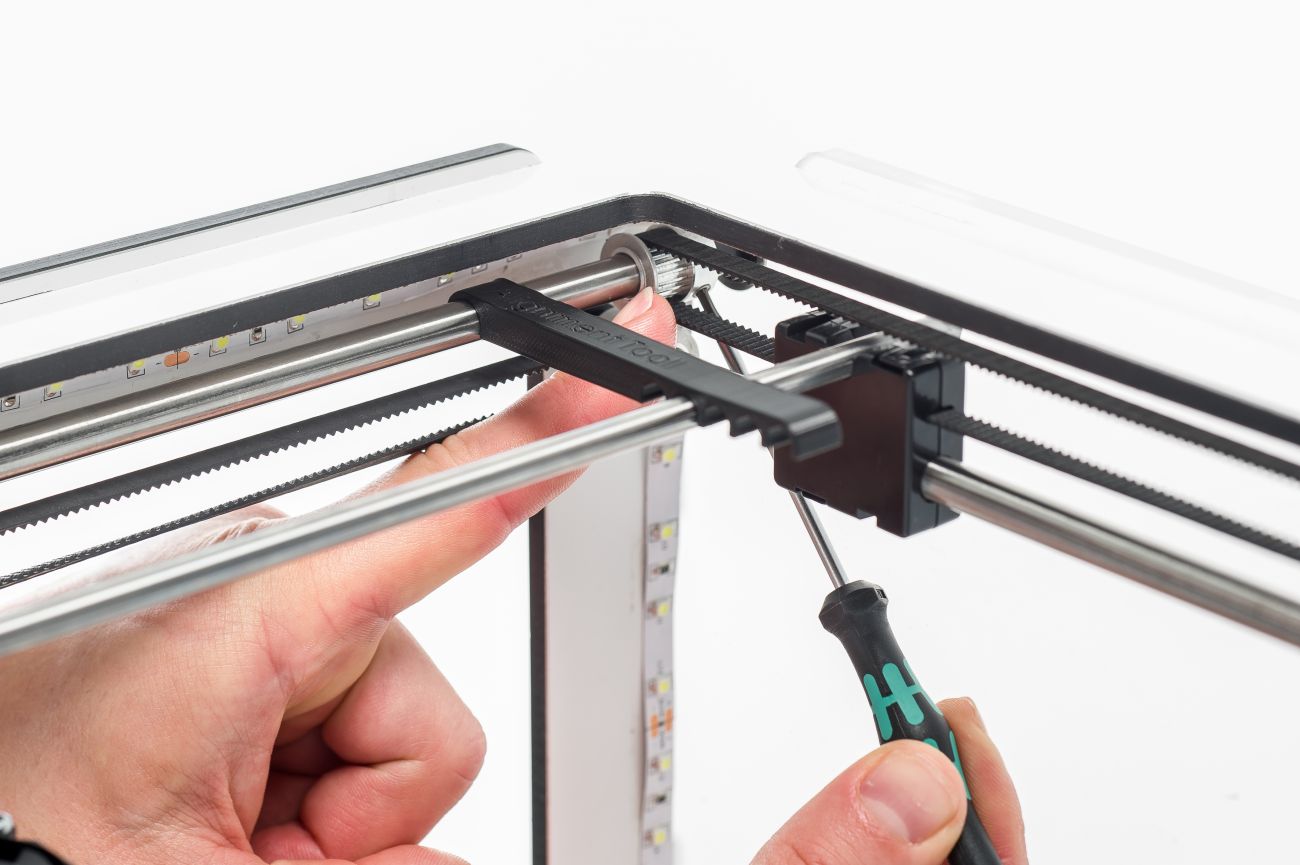

3d Printing Support Structures Troubleshooting Methods How to fix the 3d printer support structure fall? 1.modify your support structures; 2. ensure sufficient adhesion; 3. ensure sufficient adhesion 4. increase the support density. 5. tighten the grub screws. 3d printing supports may fail due to an unviable design, weak foundation, excessively heavy overhangs and bridges, slicer software issues, and extruder problems. the materials may pose teething issues, such as warping, oozing, splitting, curling, sagging, dropping, or layer shifting.

3d Printing Support Structures Troubleshooting Methods In resin 3d printing, stable support structures are critical to a successful print. when supports break during the print process, it can lead to collapsed overhangs, missing layers, and incomplete models. this guide will help you identify the signs of failed supports, understand the underlying causes, and implement eff. What is print support structure in 3d printing? does 3d printing require supports? can you 3d print without supports? bridging and overhangs; complexity of the model; orientation or rotation; do 3d printers (cura) automatically add supports? how to set up & enable 3d printing supports in cura. step 1: import the model into cura; step 2: enable. 3d printing with above supports is a good way to keep your complicated prints reliable, but they need to be just right. they may sound simple enough, but badly designed, poor quality above supports lead to a host of issues including unsound prints, uneven or rough surfaces, and unusable parts. Here’s what to do when 3d print supports are too strong: change the support settings. use tree supports. change the overhang angle. adjust the support placement. choose specific support structure shapes. use a support brim. design custom supports as part of the cad model. decrease the diameter of your points of contact.

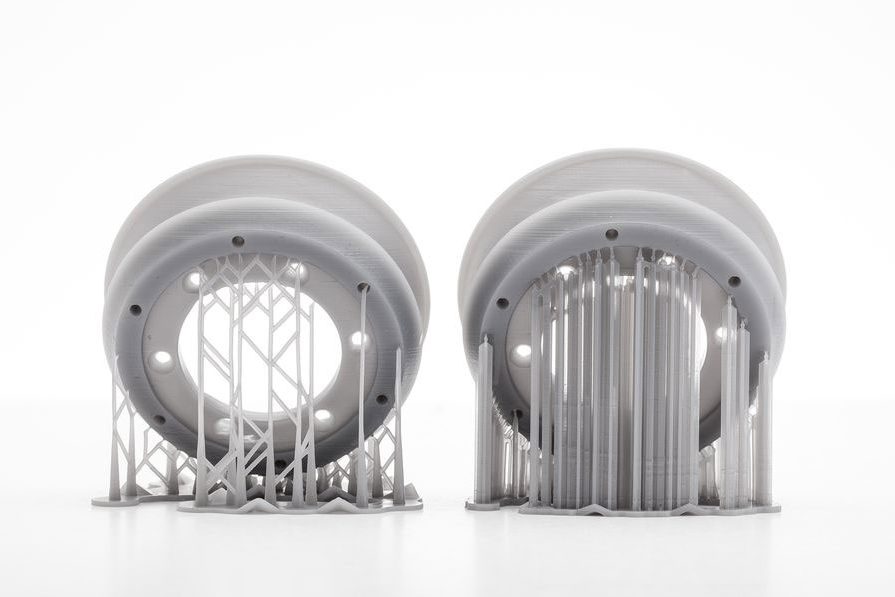

3d Printing Support Structures Troubleshooting Methods 3d printing with above supports is a good way to keep your complicated prints reliable, but they need to be just right. they may sound simple enough, but badly designed, poor quality above supports lead to a host of issues including unsound prints, uneven or rough surfaces, and unusable parts. Here’s what to do when 3d print supports are too strong: change the support settings. use tree supports. change the overhang angle. adjust the support placement. choose specific support structure shapes. use a support brim. design custom supports as part of the cad model. decrease the diameter of your points of contact. Used with almost all 3d printing technologies, support structures help to ensure the printability of a part during the 3d printing process. supports can help to prevent part deformation, secure a part to the printing bed and ensure that parts are attached to the main body of the printed part. One of the most perplexing issues that engineers and hobbyists confront is the collapsing of support structures. in this article, we delve into the intricacies of troubleshooting collapsing supports in 3d printing, facilitating improved print quality and success rates. To solve the problem of support missing or broken, we need to customize the printer and set the above parameters reasonably as well as add interconnected supports to increase the success rate of printing. Adjust your speed and temperature settings to improve overhang performance, which helps in reducing rough surfaces above supports. improve your cooling, as well as support roof settings and look towards better part orientation.