5s Audit Checklist For Manufacturing Dronahq Low Code Vrogue Co This 5s audit checklist serves as a tool for ensuring that 5s standards and workplace organization protocols are being met. it enables the observer to better identify compliance gaps and provides opportunities for continuous improvement. it comes in two different variations; one that is designed for manufacturing environments and another that. 23. 5s checklists, schedules and routines are defined and being used. 24. everyone knows his responsibilities, when and how. 25. regular audits are carried out using checklists and measures. s5 – sustain shitsuke: 26. 5s seems to be the way of life rather than just a routine. 27. success stories are being displayed (i.e. before and after.

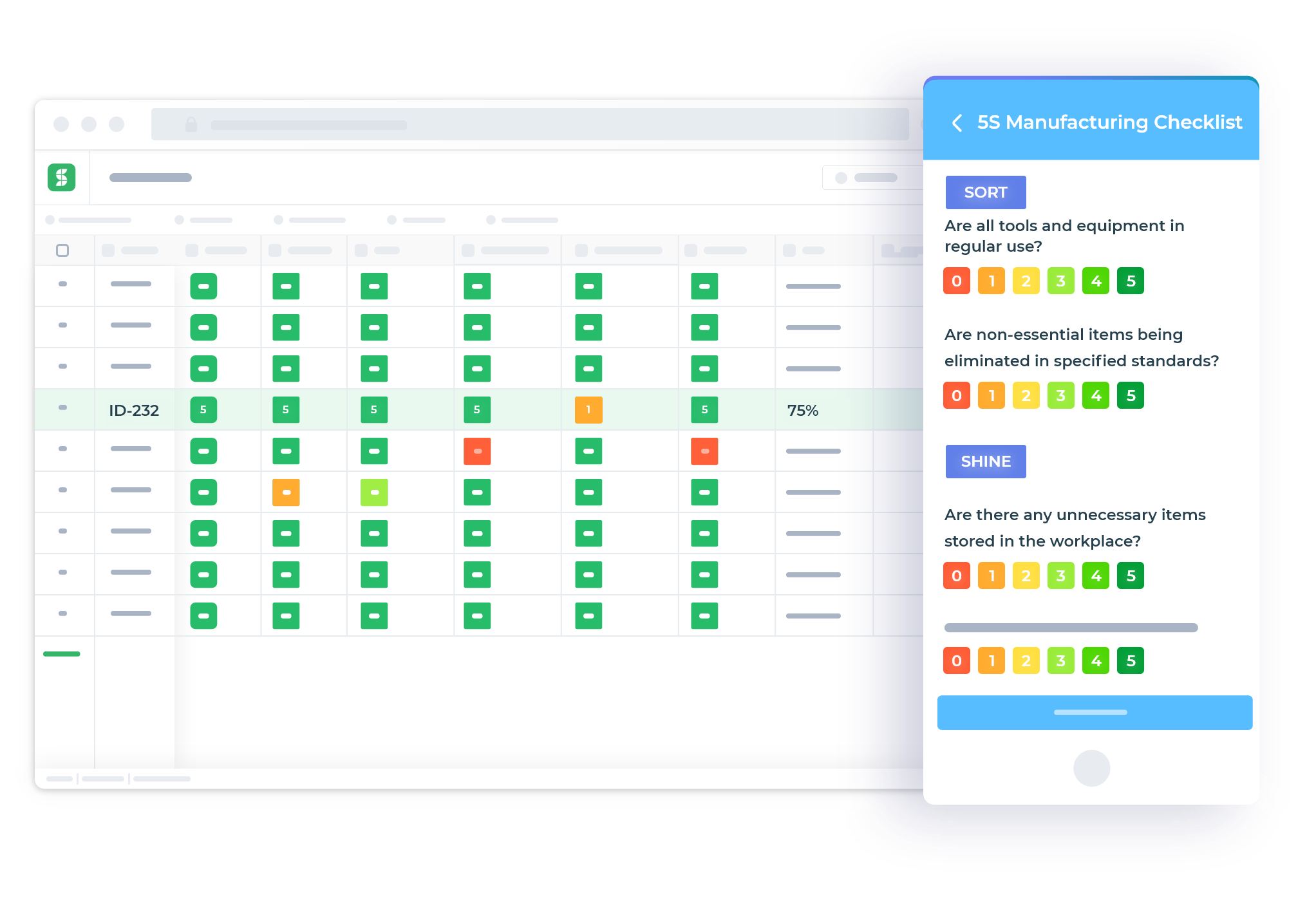

5s Audit Checklist Factory Pdf Manufactured Goods Equipment Read about 5s audits and get free access to a digital 5s audit solution with a built in 5s daily audit checklist. while traditionally done on paper, 5s audits are more comprehensive, timely, shareable, and searchable when completed on mobile devices. To conduct a 5s audit, the following steps should be taken: 1. take or attach a photo of the workplace’s current status for reference. 2. do a visual inspection of your workplace. 3. go through the questionnaire per category (sort, set in order, shine, standardize, and sustain) and assign a score. 4. Evaluate and score the current state of your 5s implementation in lean manufacturing with this free digital 5s audit checklist that features: intuitive, powerful 5s app works in manufacturing facility floors without wifi or cell signal. From dashboards and forms to admin panels and approval systems, start using ready dronahq templates in just one click. connect your data sources and start customizing the app interface. start for free.

5s Audit Of The Qad Department Assessing Sort Simplify Systematic Evaluate and score the current state of your 5s implementation in lean manufacturing with this free digital 5s audit checklist that features: intuitive, powerful 5s app works in manufacturing facility floors without wifi or cell signal. From dashboards and forms to admin panels and approval systems, start using ready dronahq templates in just one click. connect your data sources and start customizing the app interface. start for free. Get our customizable 5s audit template and supercharge your lean initiatives. the successful 5s manufacturing checklist. while we’ve shared these 33 sample questions to create your own 5s checklist for manufacturing, here’s a version that categorizes, according to each s, specific actions to be performed on the plant floor. Download lumiform’s 5s lean audit checklist for manufacturing today. take charge of your workplace organization and efficiency with this detailed checklist designed for manufacturing professionals. it guides you step by step through the key elements of 5s, making it easier to assess, streamline, and sustain improvements across your operations. The document provides a checklist for auditing a manufacturing area based on lean principles including 5s, with questions addressing sort, straighten, shine, standardization, safety, visual controls, continuous flow, training, quality, and material flow. areas are scored on implementation of lean concepts from 0 5. Download and use this free checklist while auditing your 5s implementation in business management industry.

5s Audit Checklist For Manufacturing Dronahq Low Code Platform Get our customizable 5s audit template and supercharge your lean initiatives. the successful 5s manufacturing checklist. while we’ve shared these 33 sample questions to create your own 5s checklist for manufacturing, here’s a version that categorizes, according to each s, specific actions to be performed on the plant floor. Download lumiform’s 5s lean audit checklist for manufacturing today. take charge of your workplace organization and efficiency with this detailed checklist designed for manufacturing professionals. it guides you step by step through the key elements of 5s, making it easier to assess, streamline, and sustain improvements across your operations. The document provides a checklist for auditing a manufacturing area based on lean principles including 5s, with questions addressing sort, straighten, shine, standardization, safety, visual controls, continuous flow, training, quality, and material flow. areas are scored on implementation of lean concepts from 0 5. Download and use this free checklist while auditing your 5s implementation in business management industry.