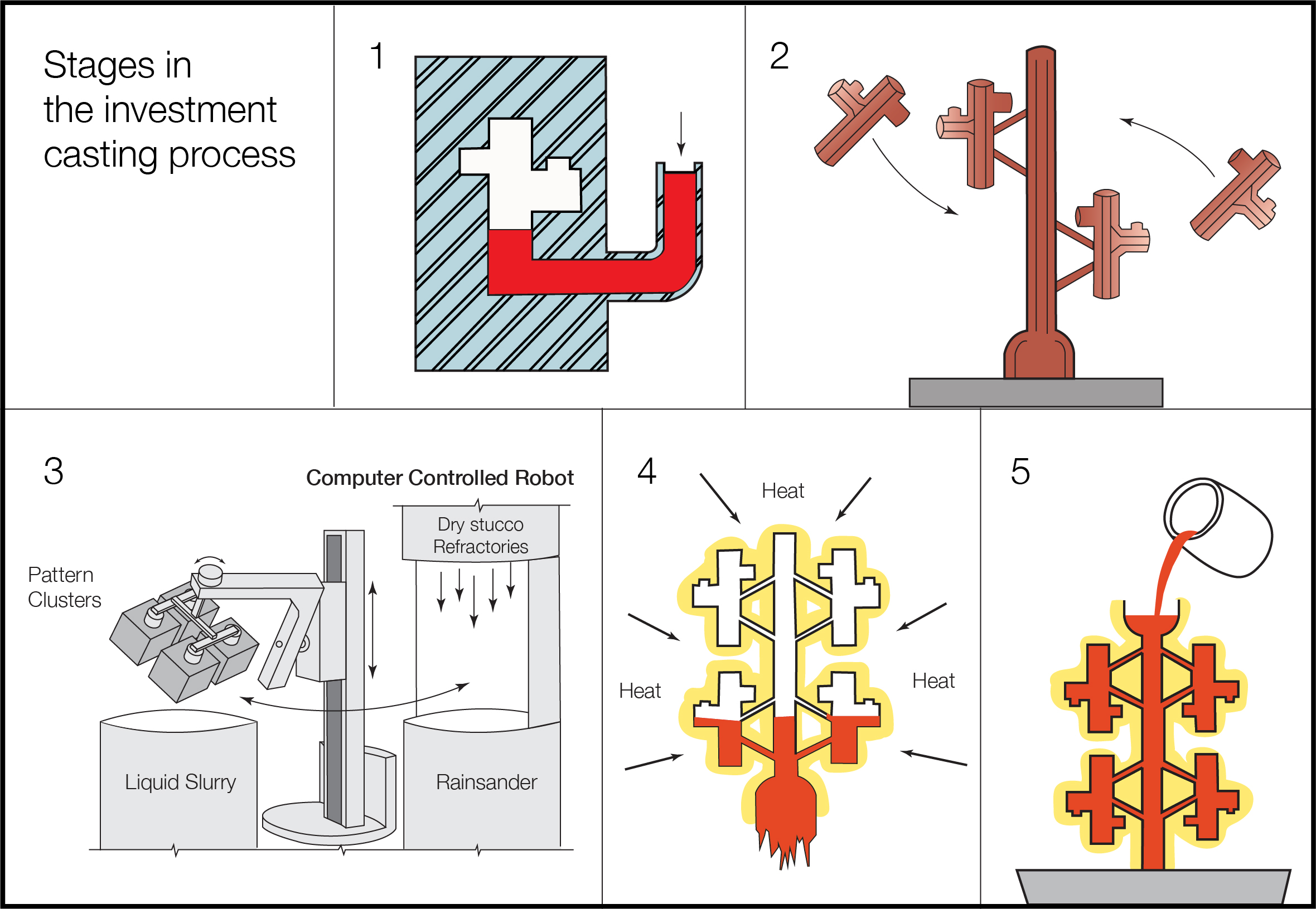

Can 3d Printing Be Used For Investment Casting How It Comes Together

Let S Learn About 3d Printing Investment Casting Together In this informative video, we’ll dive into the fascinating world of investment casting and how 3d printing is transforming this traditional manufacturing process. 3d printing investment casting improving conventional investment casting technologies by incorporating 3d printing helps achieve better, faster results while lowering cost and labor. 3d printing is already used widely to produce casting patterns, but the process using patterns still has limitations to complexity, accuracy, and lead time.

Investment Casting Or 3d Printing Ppcp Inc By using 3d printing for investment casting, you can eliminate the need for expensive molds and dies, significantly cutting down on high tooling costs. plus, you’ll be able to produce patterns overnight, drastically reducing lead times and getting your products to market faster. In addition to pattern making, 3d printing can also be used in the tooling and mold making for investment casting. while we mainly focus on using 3d printed patterns for the actual casting, we can also 3d print some of the tools and fixtures used in the investment casting process. 3d printing can integrate into the pattern creation stage of the investment casting workflow, enhancing the process in multiple ways. first, am is excellent for pattern creation, as 3d printing can be used to produce wax like or resin based patterns. By integrating 3d printed patterns into investment casting, manufacturers can shorten lead times, lower tooling costs, and produce highly complex parts with excellent repeatability.

Investment Casting Monmet 3d printing can integrate into the pattern creation stage of the investment casting workflow, enhancing the process in multiple ways. first, am is excellent for pattern creation, as 3d printing can be used to produce wax like or resin based patterns. By integrating 3d printed patterns into investment casting, manufacturers can shorten lead times, lower tooling costs, and produce highly complex parts with excellent repeatability. In particular, the application of 3d printing in investment casting offers numerous advantages. this article explores the integration of 3d printing into investment casting, highlighting its benefits, applications, and future potential. This article explores the technical integration, implementation steps, and advantages of 3d printing in precision investment casting, supported by empirical data and comparative analyses. By replacing wax patterns with 3d printed ones, manufacturers can speed up production, cut costs, and achieve design freedom like never before. here’s how 3d printing integrates with investment casting and why services like zone3dplus are leading this revolution. It’s an easy printing material capable of creating complex shapes with great smooth surface finish and will work with most desktop and industrial type fff 3d printing machines. the material decomposes at 600c and ensures a clean burnout leaving behind a clean mold ready for casting.

3d Printing And Investment Casting Engineering Product Design In particular, the application of 3d printing in investment casting offers numerous advantages. this article explores the integration of 3d printing into investment casting, highlighting its benefits, applications, and future potential. This article explores the technical integration, implementation steps, and advantages of 3d printing in precision investment casting, supported by empirical data and comparative analyses. By replacing wax patterns with 3d printed ones, manufacturers can speed up production, cut costs, and achieve design freedom like never before. here’s how 3d printing integrates with investment casting and why services like zone3dplus are leading this revolution. It’s an easy printing material capable of creating complex shapes with great smooth surface finish and will work with most desktop and industrial type fff 3d printing machines. the material decomposes at 600c and ensures a clean burnout leaving behind a clean mold ready for casting.

Investment Casting With 3d Printing By replacing wax patterns with 3d printed ones, manufacturers can speed up production, cut costs, and achieve design freedom like never before. here’s how 3d printing integrates with investment casting and why services like zone3dplus are leading this revolution. It’s an easy printing material capable of creating complex shapes with great smooth surface finish and will work with most desktop and industrial type fff 3d printing machines. the material decomposes at 600c and ensures a clean burnout leaving behind a clean mold ready for casting.

Using 3d Printing In The Investment Casting Process

Comments are closed.