Additive Versus Subtractive Manufacturing Pdf Computer Aided Design Additive processes are suitable for a narrow range of materials. subtractive processes pose no restriction on working material. it is suitable for small size components. it cannot accommodate large components. it can process small to large objects. any complex shape can be directly produced by these processes. Additive manufacturing is ideal for low volume, customized, or prototype parts. lead time: additive manufacturing offers shorter lead times for prototyping, while subtractive methods are better for established production runs. additive vs. subtractive systems. both additive and subtractive manufacturing systems have their place in modern.

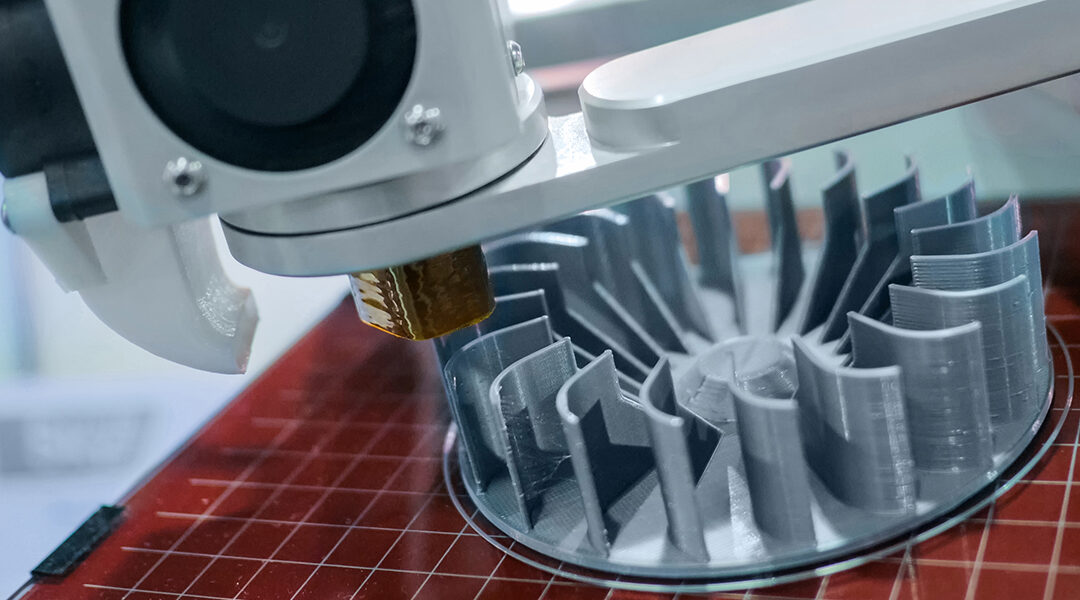

Difference Between Additive And Subtractive Manufacturing Additive manufacturing is a process that adds successive layers of material to create an object, often referred to as 3d printing. subtractive manufacturing, as the name suggests, is the opposite. rather than adding layers, subtractive manufacturing involves removing sections of a material by machining or cutting it away. Additive and subtractive manufacturing produce a wide range of products across several industries. additive manufacturing is preferred for rapid prototyping, small batch production, and on demand production. subtractive manufacturing has long produced prototypes but is best suited for large production runs. Additive manufacturing is a process that adds successive layers of material to create an object, often referred to as 3d printing. subtractive manufacturing, as the name suggests, is the opposite. rather than adding layers, subtractive manufacturing involves removing sections of a material by machining or cutting it away. Additive manufacturing is often favored for small batch production and on demand manufacturing, which can significantly reduce waste and inventory costs. on the other hand, subtractive manufacturing is well established for mass production, where the initial setup costs can be amortized over a large number of units.

What S The Difference Between Additive And Subtractive Manufacturing Additive manufacturing is a process that adds successive layers of material to create an object, often referred to as 3d printing. subtractive manufacturing, as the name suggests, is the opposite. rather than adding layers, subtractive manufacturing involves removing sections of a material by machining or cutting it away. Additive manufacturing is often favored for small batch production and on demand manufacturing, which can significantly reduce waste and inventory costs. on the other hand, subtractive manufacturing is well established for mass production, where the initial setup costs can be amortized over a large number of units. Additive and subtractive manufacturing are two approaches to producing parts and products. additive manufacturing creates final products by adding material layer by layer, while subtractive manufacturing involves removing material from a larger piece to make the final product. What are the main differences between additive and subtractive manufacturing? additive manufacturing (am) and subtractive manufacturing (sm) differ fundamentally in their approaches: am builds objects layer by layer, adding material only where needed, which minimizes waste and allows for complex geometries and customization. What is the main difference between additive and subtractive manufacturing processes? additive and subtractive manufacturing processes differ in their basic principle of operation. additive manufacturing processes work by adding materials into the shape you require.

Additive Vs Subtractive Manufacturing What Are The 52 Off Additive and subtractive manufacturing are two approaches to producing parts and products. additive manufacturing creates final products by adding material layer by layer, while subtractive manufacturing involves removing material from a larger piece to make the final product. What are the main differences between additive and subtractive manufacturing? additive manufacturing (am) and subtractive manufacturing (sm) differ fundamentally in their approaches: am builds objects layer by layer, adding material only where needed, which minimizes waste and allows for complex geometries and customization. What is the main difference between additive and subtractive manufacturing processes? additive and subtractive manufacturing processes differ in their basic principle of operation. additive manufacturing processes work by adding materials into the shape you require.

Subtractive Manufacturing Vs Additive Manufacturing What S The Difference What is the main difference between additive and subtractive manufacturing processes? additive and subtractive manufacturing processes differ in their basic principle of operation. additive manufacturing processes work by adding materials into the shape you require.

What Is The Difference Between Additive Manufacturing And Subtractive