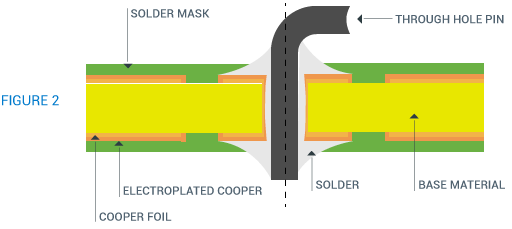

Plated Through Holes Non Plated Through Holes Printed Circuit Plated through holes have a conductive metallic coating along their walls, providing electrical connectivity between pcb layers, while non plated through holes are simply mechanical holes without any conductive coating, typically used for mounting and alignment purposes. In printed circuit board (pcb) designs, through holes are used to connect components and conductors on different layers of the board and can be divided into two types: plated and non plated through holes. plated through holes are holes in the pcb that have a metal layer coating the inside of the hole, which is used to create electrical.

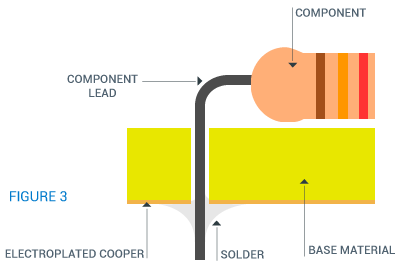

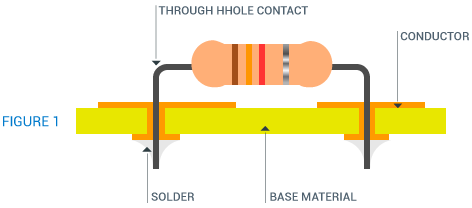

Plated Through Holes Non Plated Through Holes Printed Circuit Through hole technology, also spelled "thru hole" are holes that go completely through the boards. they can be plated (pth) or non plated (npth). with plated through holes there is a conductive path from one side of the board to the other, as seen on figure 1. The easiest way to distinguish between plating through hole and non plating through hole pcbs is by visually checking for traces of plating on the borehole wall in the pcb. non plating through hole pcbs will not have any traces of copper in the borehole wall. What is the difference between a plated through hole and a non plated one? what is through hole plating? how are pcbs plated? try our free better dfm tool and save time and money. our automated platform will catch any pcb design error ahead of time and prevent on holds and re spins. Today, the most pcbs are double sided, or multi layered, and most of the through holes are plated. the components can connect to the required layers in the board. plated through holes can also be plated slots, plated half holes (castellated holes), not always round in shape.

Plated Through Holes Non Plated Through Holes Printed Circuit What is the difference between a plated through hole and a non plated one? what is through hole plating? how are pcbs plated? try our free better dfm tool and save time and money. our automated platform will catch any pcb design error ahead of time and prevent on holds and re spins. Today, the most pcbs are double sided, or multi layered, and most of the through holes are plated. the components can connect to the required layers in the board. plated through holes can also be plated slots, plated half holes (castellated holes), not always round in shape. Non plated through holes are simple features that are either drilled or milled through your circuit board, which expressly do not receive a plating of conductive copper. typical uses of npth features are mounting holes to allow screws or other fasteners to pass through your board. what is plated through hole in pcb?. The mounting holes used in a pcb can be plated or non plated, depending on the type of fastener and the type of enclosure. if you’re unsure of which type to use and how to quickly change them in the pcb layout, keep reading to learn more. As the name suggests, these vias connect the outermost layers because they extend from top to bottom. also known as plated through vias, these holes create an electrical connection between all the pcb layers. they are the easiest and cheapest to make but can take up a lot of space.

What S The Difference Between Non Plated And Plated Badges Smith Non plated through holes are simple features that are either drilled or milled through your circuit board, which expressly do not receive a plating of conductive copper. typical uses of npth features are mounting holes to allow screws or other fasteners to pass through your board. what is plated through hole in pcb?. The mounting holes used in a pcb can be plated or non plated, depending on the type of fastener and the type of enclosure. if you’re unsure of which type to use and how to quickly change them in the pcb layout, keep reading to learn more. As the name suggests, these vias connect the outermost layers because they extend from top to bottom. also known as plated through vias, these holes create an electrical connection between all the pcb layers. they are the easiest and cheapest to make but can take up a lot of space.