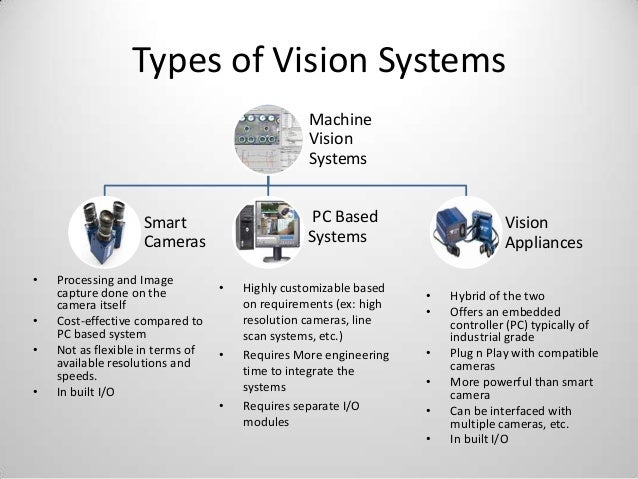

Qualitas Technologies Vision Oem In this article, we categorized machine vision systems into three major types: smart camera based vision system, compact vision system, and pc based vision system. once correctly implemented, modifying or replacing the machine vision systems can incur you a lot of your valuable time and a considerable amount of money. Also, read– different types of vision systems. types of hardware architecture. hardware is the most visible component of a machine vision system. the type of inspection and speed of inspection plays an important role in determining the hardware. there are two types of hardware architecture –.

Machine Vision Company Qualitas Technologies Building Image For choosing a suitable machine vision camera, a few questions can help you identify the requisite key imaging characteristics for your system: what kind of object do you intend to inspect? how does the system interact with the existing infrastructure? what kind of light sources is being used for illumination and imaging?. Qualitas technologies enables manufacturing industries to realize the potential of ai and machine vision in order to automate visual inspection processes. automate visual inspection in manufacturing by making a 10x improvement in cost and efficiency. the 7 elements of a machine vision system industrial vision systems. 2d vision systems provide area scans that work well for discrete parts. these systems are compatible with most software packages and are the default technology used for most machine vision applications. 2d systems are available in a continually expanding range of resolutions. This document discusses machine vision and various components of machine vision systems. it describes different types of sensors used in machine vision like cameras, frame grabbers, and describes the process of sensing and digitizing image data through analog to digital conversion, image storage, and lighting techniques.

Qualitas Technologies Vision Oem Ppt 2d vision systems provide area scans that work well for discrete parts. these systems are compatible with most software packages and are the default technology used for most machine vision applications. 2d systems are available in a continually expanding range of resolutions. This document discusses machine vision and various components of machine vision systems. it describes different types of sensors used in machine vision like cameras, frame grabbers, and describes the process of sensing and digitizing image data through analog to digital conversion, image storage, and lighting techniques. In this article, we will delve into three prominent types of vision systems – robotic vision systems, conveyor based vision systems, and stationary vision inspection systems – and explore their roles in quality inspection, defect detection, product classification, grading, product mix, item counting, and item weighing. Types of vision systems used in manufacturing. machine vision systems have many applications in the industrial world, many of which require specialized systems to accomplish the task at hand. however, most vision systems fall under three different classes: pc based, smart camera based, and compact vision systems. 1. pc based vision systems. The components of machine vision systems are lighting, lens, image sensors, vision processing unit, and communication system. the types of machine vision lighting are back lighting, diffuse lighting, partial bright field lighting, and dark field lighting. While commercial cameras offer good resolution and cheaper options, they cannot be used in vision systems because machine vision cameras serve entirely different purposes. some critical features of a machine vision camera are: high shutter speed and frame rates; robustness and reliability; programmatic access to camera parameters; electronic.

Vision Systems October 2018 In this article, we will delve into three prominent types of vision systems – robotic vision systems, conveyor based vision systems, and stationary vision inspection systems – and explore their roles in quality inspection, defect detection, product classification, grading, product mix, item counting, and item weighing. Types of vision systems used in manufacturing. machine vision systems have many applications in the industrial world, many of which require specialized systems to accomplish the task at hand. however, most vision systems fall under three different classes: pc based, smart camera based, and compact vision systems. 1. pc based vision systems. The components of machine vision systems are lighting, lens, image sensors, vision processing unit, and communication system. the types of machine vision lighting are back lighting, diffuse lighting, partial bright field lighting, and dark field lighting. While commercial cameras offer good resolution and cheaper options, they cannot be used in vision systems because machine vision cameras serve entirely different purposes. some critical features of a machine vision camera are: high shutter speed and frame rates; robustness and reliability; programmatic access to camera parameters; electronic.