Pth Through Hole Assembly Pcb Technologies Andwin Circuits Electronics: non plated through hole to pthhelpful? please support me on patreon: patreon roelvandepaarwith thanks & praise to god, and with. Do you have a 2 layer, or more layer board? if you have a 2 layer board, then you can do a repair, as you have access to both top and bottom copper. clean them of any solder resist round the hole, and pass a pin or wire through the hole, and solder top and bottom.

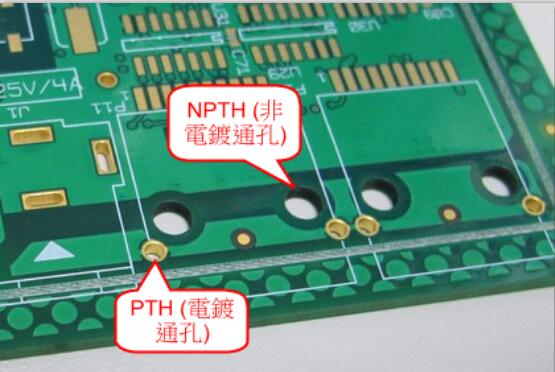

Plated Through Hole Pth In Pcb Fabrication Rf Pcb Plated through holes have a conductive metallic coating along their walls, providing electrical connectivity between pcb layers, while non plated through holes are simply mechanical holes without any conductive coating, typically used for mounting and alignment purposes. Converting pth to npth: this can be done by mechanically removing the plating from the hole walls using specialized tools. while this approach is possible, it can weaken the mechanical strength of the hole and compromise the pcb’s structural integrity. Through hole technology, also spelled "thru hole" are holes that go completely through the boards. they can be plated (pth) or non plated (npth). with plated through holes there is a conductive path from one side of the board to the other, as seen on figure 1. N pth is non plated through hole. to help you understand its meaning more clearly, we will dismantle and explain this word: “plating” refers to the process of placing a pcb in a solution of metal ions and depositing metal ions at specified locations through the application of an electric current.

Circuit Board Pth Plating Through Hole Npth Non Plated Through Hole Through hole technology, also spelled "thru hole" are holes that go completely through the boards. they can be plated (pth) or non plated (npth). with plated through holes there is a conductive path from one side of the board to the other, as seen on figure 1. N pth is non plated through hole. to help you understand its meaning more clearly, we will dismantle and explain this word: “plating” refers to the process of placing a pcb in a solution of metal ions and depositing metal ions at specified locations through the application of an electric current. Given the description of pth above, non plating through holes follow the similar rules. the primary difference is that the inside surfaces of the holes are not plated in conductive materials. an npth does not serve the same purposes as a pth, as it cannot pass any current through it. Non plated thru holes are holes on a printed circuit board that have not been plated with conductive metals. their use is normally mechanical: mainly, housing screws, fasteners, alignment, and attaching big components or the board itself during its assembling process. Plated through holes can also be plated slots, plated half holes (castellated holes), not always round in shape. non plated through hole (npth) : from its name, this type of through holes no copper plated onto the walls of the holes, so the barrel of the hole has not electrical properties. Non plated through hole technology is a simpler and more cost effective alternative to plated through hole technology. in non plated through hole pcbs, the holes drilled through the pcb have no metal. the components are inserted and soldered to the pads on both sides of the pcb.