Encyclopedia Articles On Laser Material Processing

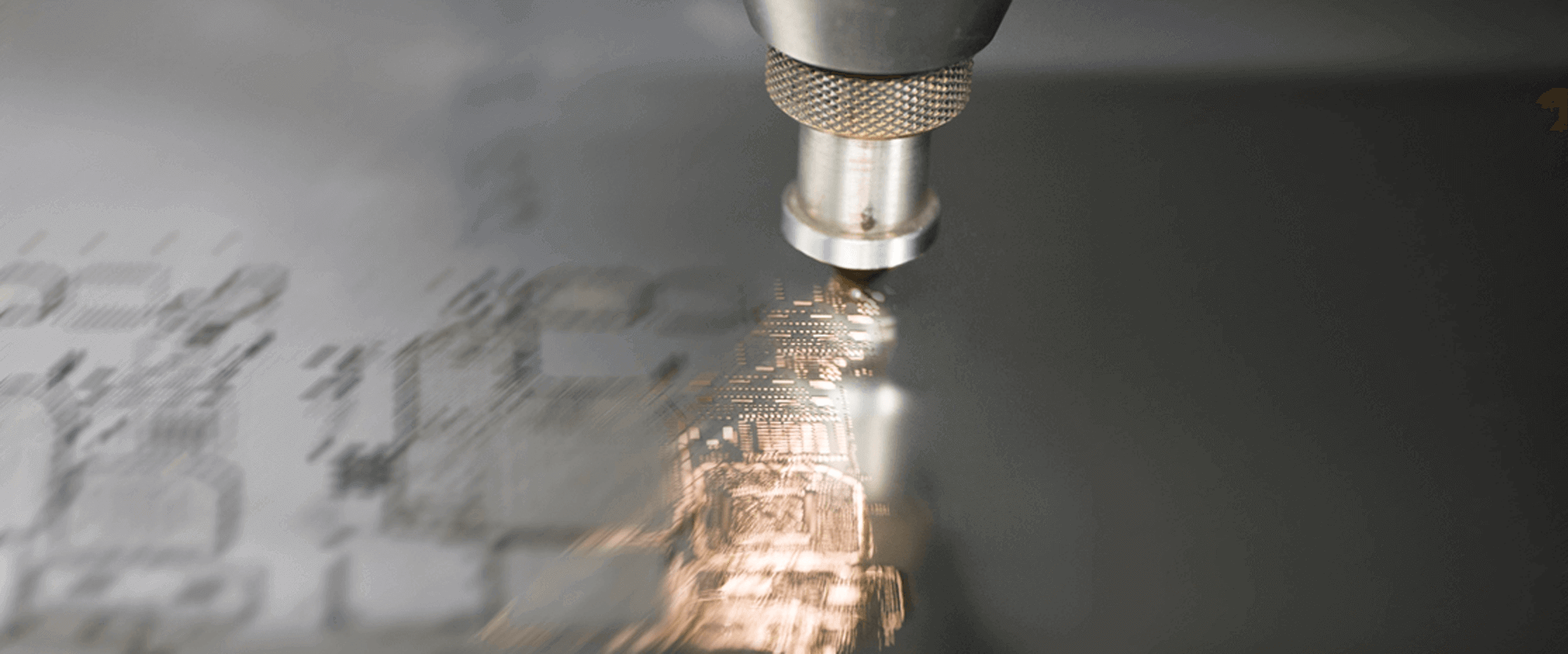

Laser Wikipedia The Free Encyclopedia Pdf Laser Laser Diode The rp photonics encyclopedia covers the field of laser material processing quite comprehensively and carefully. for example, it explains underlying physical principles and resulting limitations. Laser material processing is defined as a non contact manufacturing operation that utilizes high intensity pulsed laser light for tasks such as cutting, drilling, welding, and engraving, allowing for precise control and minimal mechanical stress on materials.

Lecture 19 Laser Materials Processing Pdf Coherence Physics Laser The informal style of laser material processing (4th edition) will guide you smoothly from the basics of laser physics to the detailed treatment of all the major materials processing techniques for which lasers are now essential. Topics such as various types of laser processing, including additive manufacturing, ablation, polishing, and micromachining, are covered by this special issue, presenting recent developments and achievements in the laser processing of traditional and the most advanced metal based materials. At the beginning, a brief introduction to different types of lasers and their general applications, fundamentals of laser‐matter interaction and classification of laser material processing. The result is that choosing the right laser for a specific application is now a more complex task than in the past. this article reviews the technology and capa bilities of all these laser types and pro vides guidance on identifying the optimal source for a specific need.

Laser Materials Processing At the beginning, a brief introduction to different types of lasers and their general applications, fundamentals of laser‐matter interaction and classification of laser material processing. The result is that choosing the right laser for a specific application is now a more complex task than in the past. this article reviews the technology and capa bilities of all these laser types and pro vides guidance on identifying the optimal source for a specific need. The general areas of industrial material processing which are discussed here are 1) welding, 2) cutting and drilling, and 3) surface hardening. the basic mechanisms involved in these processes are discussed and both theoretical and experimental results are described. This chapter gives the author's view (based on 25 years of research and development in laser processing) on the challenges and future prospects of laser materials processing research. Lasers are widely used for laser material processing – mostly in manufacturing, e.g. for cutting, drilling, welding, cladding, soldering (brazing), hardening, surface modification, marking, engraving, micromachining, pulsed laser deposition, lithography, etc. This continuously leads to a significant flow of research into the most diverse aspects of this technology, namely in cutting, welding, texturing, engraving operations, and, more recently, three dimensional (3d) printing of various materials.

Laser Material Processing Laserjob The general areas of industrial material processing which are discussed here are 1) welding, 2) cutting and drilling, and 3) surface hardening. the basic mechanisms involved in these processes are discussed and both theoretical and experimental results are described. This chapter gives the author's view (based on 25 years of research and development in laser processing) on the challenges and future prospects of laser materials processing research. Lasers are widely used for laser material processing – mostly in manufacturing, e.g. for cutting, drilling, welding, cladding, soldering (brazing), hardening, surface modification, marking, engraving, micromachining, pulsed laser deposition, lithography, etc. This continuously leads to a significant flow of research into the most diverse aspects of this technology, namely in cutting, welding, texturing, engraving operations, and, more recently, three dimensional (3d) printing of various materials.

Comments are closed.