Figure 2 From Modeling Simultaneous Effects Of Water Hammer And

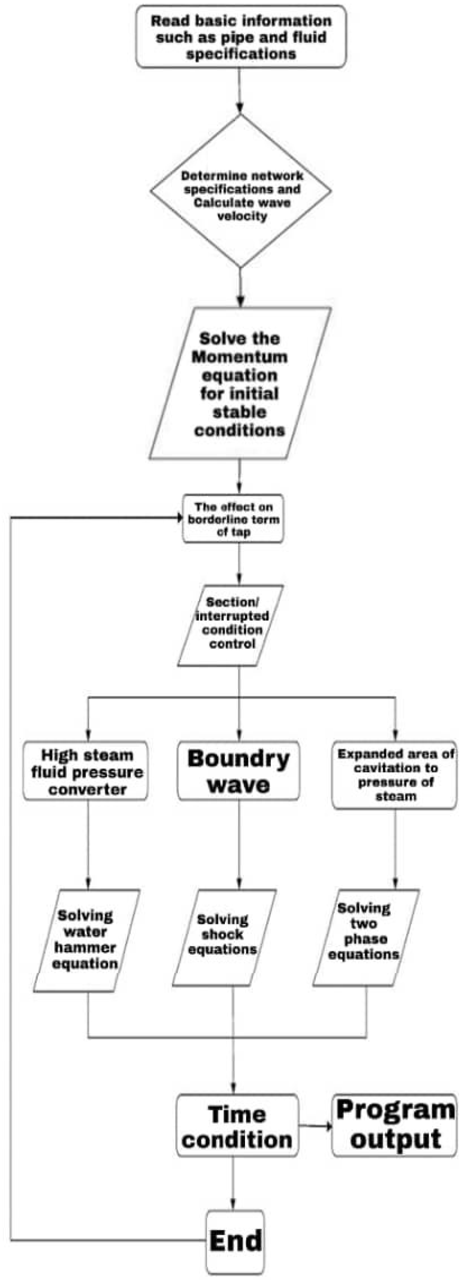

Effects Of Water Hammer Pdf Valve Fluid Mechanics In this study, in order to investigate the ram impact phenomenon along with cavitation, a flow model in pipes in two dimensional (quasi two dimensional) space has been developed. Water hammer refers to pressure fluctuations caused by changes in fluid speed in hydraulic systems. this research proposes a model using the maccormack method to study and control water hammer, specifically focusing on managing valve closure to reduce shock wave pressure during transient flow.

Simulation Of Multiphase Fluid Hammer Effects During Well Startup And The hydraulic model is formulated and solved by the method of characteristics using the differential equations of momentum and continuity combined which are developed for solving transient. To address the objectives stated in section 1.2, the thesis outlines the relative works of water hammer models and details the derivation of newly proposed boundary expression for the upstream reservoir, as well as the development of the finite element and two way coupling water hammer models. To investigate the sole simultaneous effect of poisson and or junction coupling and viscoelasticity, a hypothetical case study is considered and the corresponding results are closely investigated. An actual water delivery project was then simulated to validate the accuracy and effectiveness of the proposed integrated protection strategy. results confirm that the coordinated deployment of protective components, along with pump valve linkage control, substantially mitigates water hammer effects.

Effects Of Water Hammer Download Scientific Diagram To investigate the sole simultaneous effect of poisson and or junction coupling and viscoelasticity, a hypothetical case study is considered and the corresponding results are closely investigated. An actual water delivery project was then simulated to validate the accuracy and effectiveness of the proposed integrated protection strategy. results confirm that the coordinated deployment of protective components, along with pump valve linkage control, substantially mitigates water hammer effects. Water hammer, also known as hydraulic shock or surge, is a sudden pressure increase or shockwave that occurs within a fluid carrying pipe system when there is a rapid change in flow velocity. it happens due to the inertia of the moving fluid and the compressibility of water. The water hammer effect of hydraulic system is the fatal hazard of aircraft hydraulic system, so at the beginning of the design of aircraft hydraulic system, it is necessary to consider the impact of water hammer on the system in detail to avoid possible problems in advance. Valve closure time is a critical parameter influencing pressure magnitude, necessitating precise calibration to ensure system safety. while numerical methods like the maccormack scheme provide accurate solutions, their computational intensity limits practical applications. The study employs a finite volume method (fvm) to analyze water hammer, starting with water as a baseline due to its well defined properties and experimental data.

Figure 2 From Modeling Simultaneous Effects Of Water Hammer And Water hammer, also known as hydraulic shock or surge, is a sudden pressure increase or shockwave that occurs within a fluid carrying pipe system when there is a rapid change in flow velocity. it happens due to the inertia of the moving fluid and the compressibility of water. The water hammer effect of hydraulic system is the fatal hazard of aircraft hydraulic system, so at the beginning of the design of aircraft hydraulic system, it is necessary to consider the impact of water hammer on the system in detail to avoid possible problems in advance. Valve closure time is a critical parameter influencing pressure magnitude, necessitating precise calibration to ensure system safety. while numerical methods like the maccormack scheme provide accurate solutions, their computational intensity limits practical applications. The study employs a finite volume method (fvm) to analyze water hammer, starting with water as a baseline due to its well defined properties and experimental data.

Comments are closed.