Flowchart Pp Engineering Pdf

Flowchart Pp Engineering Pdf Flowchart pp engineering free download as pdf file (.pdf), text file (.txt) or view presentation slides online. this document outlines the process for ordering spare parts and materials for work ipos (industrial project orders) within a company. This training manual provides a step by step to sap pp processes with all steps having screenshots and clear instructions. see below the outline of the document:.

Flowchart Pp Pdf Chemical engineering process design is the design of processes for the desired physicaland or chemicaltransformations of substances. introduction to design • design is a creative activity, actually can be regarded as an art. • the design does not exist at the start of the project. A high level flowchart, outlining 6 10 major steps, gives a high level view of a process. these flowcharts display the major blocks of activity, or the major system components, in a process. Process flow diagram a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. the pfd displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Block diagrams are useful for representing a process in a simplified form in reports, textbooks and presentations, but have limited use as engineering documents.

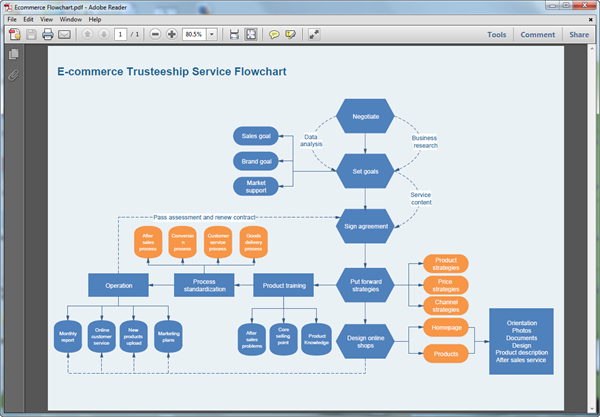

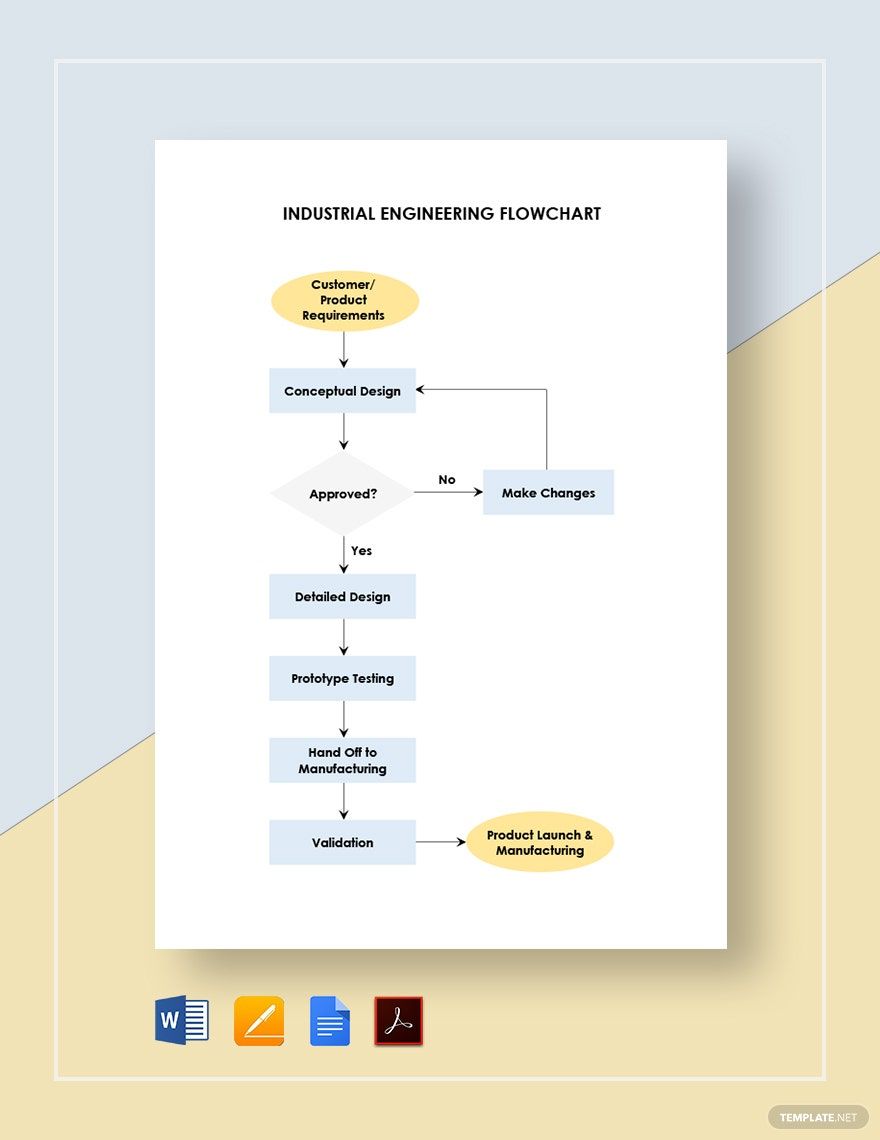

Engineering Process Flow Chart Image To U Process flow diagram a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. the pfd displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Block diagrams are useful for representing a process in a simplified form in reports, textbooks and presentations, but have limited use as engineering documents. Instantly download engineering flowchart template, sample & example in microsoft word (doc), apple pages, google docs, pdf format. available in a4 & us letter sizes. Pp flow chart free download as pdf file (.pdf), text file (.txt) or read online for free. This document summarizes the engineering work flow process: 1. the process begins with a contract acceptance meeting and file transfer with relevant documents. Figure 1 presents the shrinkage of polypropylene versus wall thickness in injection molded parts. these data were obtained from many and varied pieces molded from different grades of polypropylene. consequently, a range is shown for any wall thickness.

Create Flowchart For Pdf On Mac Edraw Instantly download engineering flowchart template, sample & example in microsoft word (doc), apple pages, google docs, pdf format. available in a4 & us letter sizes. Pp flow chart free download as pdf file (.pdf), text file (.txt) or read online for free. This document summarizes the engineering work flow process: 1. the process begins with a contract acceptance meeting and file transfer with relevant documents. Figure 1 presents the shrinkage of polypropylene versus wall thickness in injection molded parts. these data were obtained from many and varied pieces molded from different grades of polypropylene. consequently, a range is shown for any wall thickness.

Editable Engineering Flowchart Template In Pdf Word Pages Google This document summarizes the engineering work flow process: 1. the process begins with a contract acceptance meeting and file transfer with relevant documents. Figure 1 presents the shrinkage of polypropylene versus wall thickness in injection molded parts. these data were obtained from many and varied pieces molded from different grades of polypropylene. consequently, a range is shown for any wall thickness.

Flowchart Eng Pdf Teknologi Rekayasa

Comments are closed.