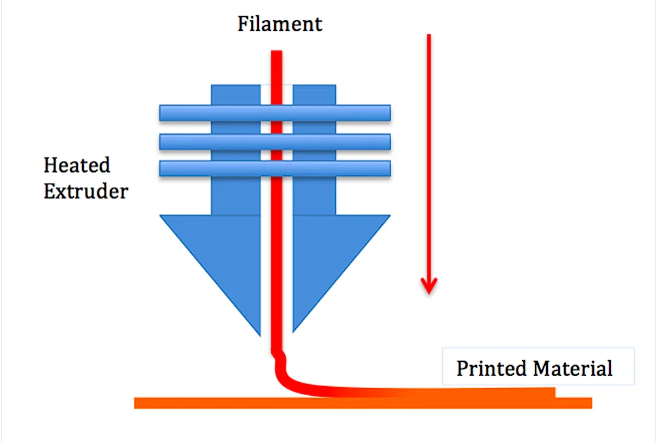

Fused Deposition Modeling Fdm 3d Printing Simply Explained Facfox Docs Fused deposition modeling, or fdm 3d printing, is a method of additive manufacturing where layers of materials are fused together in a pattern to create an object. the material is usually melted just past its glass transition temperature, and then extruded in a pattern next to or on top of previous extrusions, creating an object layer by layer. What is fdm? fused deposition modeling (fdm), or fused filament fabrication (fff), is an additive manufacturing process that belongs to the material extrusion family. in fdm, an object is built by selectively depositing melted material in a pre determined path layer by layer. the materials used are thermoplastic polymers and come in a filament.

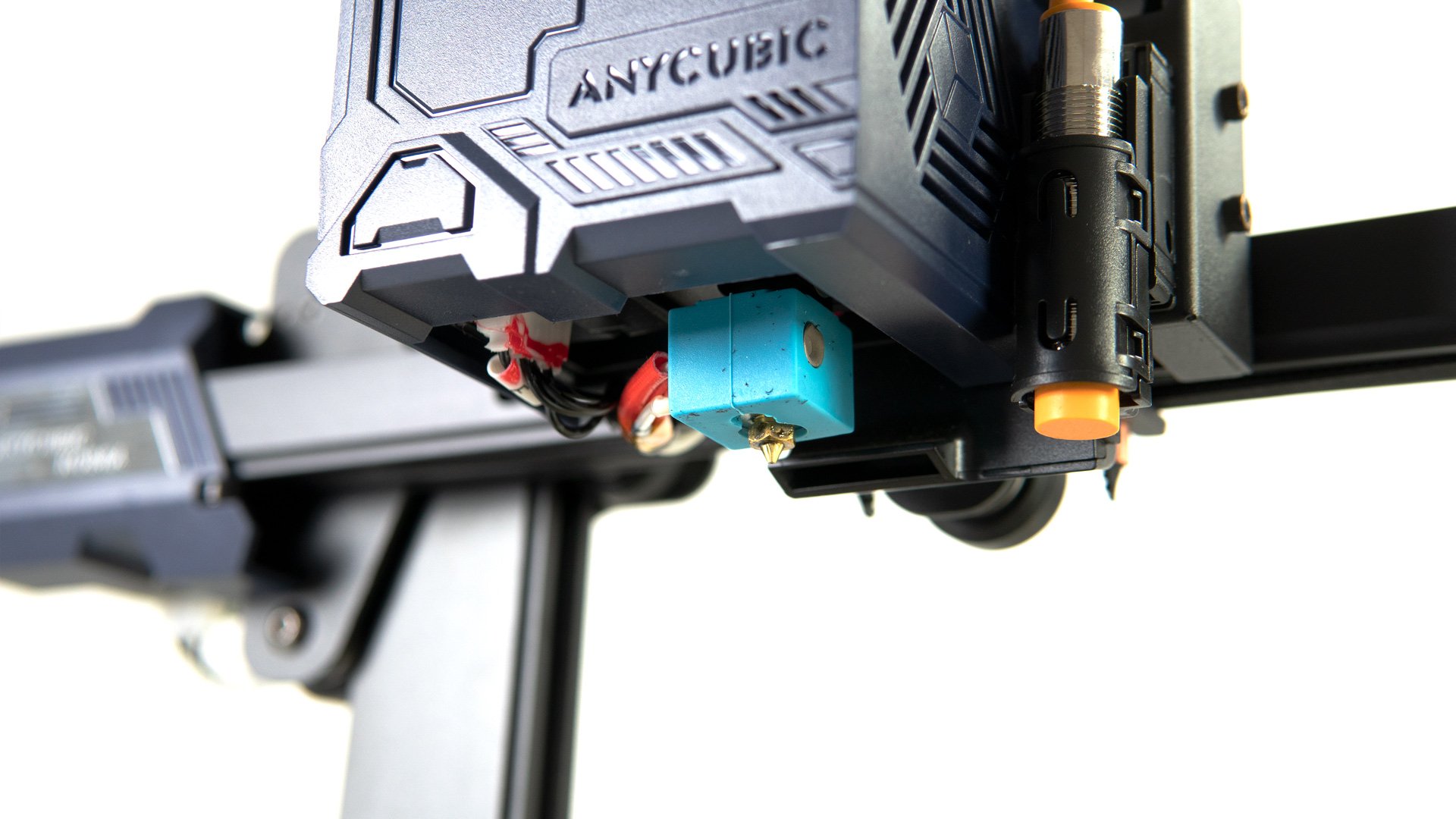

Fused Deposition Modeling Fdm And Its Main Limitations Ic3d Printers Fdm stands for fused deposition modeling, sometimes also known as fused filament fabrication. fdm 3d printing belongs to the material extrusion family. this technology represents the widest installed base of 3d printers globally. and is, therefore, the first technology that a newbie in additive manufacturing is made familiar with. Fdm is the most popular 3d printing technology. learn all you need to know about it and how it compares to other methods. Fused deposition modeling (also known as fdm), is the most commonly used 3d printing technology for everyday makers and consumers. in this article, 3dsourced explain: the history of fdm; how to set up an fdm 3d printer; the fdm printing process; and which 3d printer filaments and materials to use. Fused deposition modeling (fdm) or fused filament fabrication (fff) is the most widely adopted 3d printing technology. in this explanation, we will delve into the origins of this technology and how it operates.

What Is Fdm 3d Printing Simply Explained All3dp Fused deposition modeling (also known as fdm), is the most commonly used 3d printing technology for everyday makers and consumers. in this article, 3dsourced explain: the history of fdm; how to set up an fdm 3d printer; the fdm printing process; and which 3d printer filaments and materials to use. Fused deposition modeling (fdm) or fused filament fabrication (fff) is the most widely adopted 3d printing technology. in this explanation, we will delve into the origins of this technology and how it operates. Fused deposition modeling (fdm) 3d printing, also known as fused filament fabrication (fff), is an additive manufacturing (am) process within the realm of material extrusion. fdm builds parts layer by layer by selectively depositing melted material in a predetermined path. Fused deposition modeling 3d printing is a method of additive manufacturing where layers of materials are fused in a pattern to create an object. it melts the material just past its glass transition temperature and extrudes it in a pattern next to or on to of the previous extrusions to create an object layer by layer. Fused deposition modeling, or fdm 3d printing, is a method of additive manufacturing where layers of materials are fused together in a pattern to create an object. the material is usually melted just past its glass transition temperature, and then extruded in a pattern next to or on top of previous extrusions, creating an object layer by layer. Fused deposition modeling is currently recognized as one of the best 3d printing technologies for various goals. being accessible, straightforward, versatile, highly customizable, and increasingly cost efficient, fdm 3d printing provides sufficient accuracy, quality, and performance to meet manifold additive manufacturing needs on both beginner.