Fused Deposition Modeling Fdm And Its Main Limitations Ic3d Printers Fused deposition modelling (fdm) is an advanced 3d printing technique for the manufacture of plastic materials. the ease of use, prototyping accuracy and low cost makes it a widely used additive manufacturing technique. fdm creates 3d structures through the layer by layer melt extrusion of a plastic filament. In this article, we explain why this technology is an efficient and cost effective choice for rapid prototyping and other applications. fused deposition modeling (fdm) 3d printing, also known as fused filament fabrication (fff), is an additive manufacturing (am) process within the realm of material extrusion.

Fused Deposition Modeling Fdm 3d Printing Technology How It 43 Off Fused deposition modeling (also known as fdm), is the most commonly used 3d printing technology for everyday makers and consumers. in this article, 3dsourced explain: the history of fdm; how to set up an fdm 3d printer; the fdm printing process; and which 3d printer filaments and materials to use. Researchers have recently investigated many approaches for expanding the range of materials and optimizing the fdm process parameters to extend the fdm process’s possibility into various. This survey provides a thorough examination of fused deposition mod eling (fdm), a prevalent 3d printing technology known f or its accessibility an d versatility. fdm has emerged as a. Fused deposition modeling (fdm) or fused filament fabrication (fff) is the most widely adopted 3d printing technology. in this explanation, we will delve into the origins of this technology and how it operates.

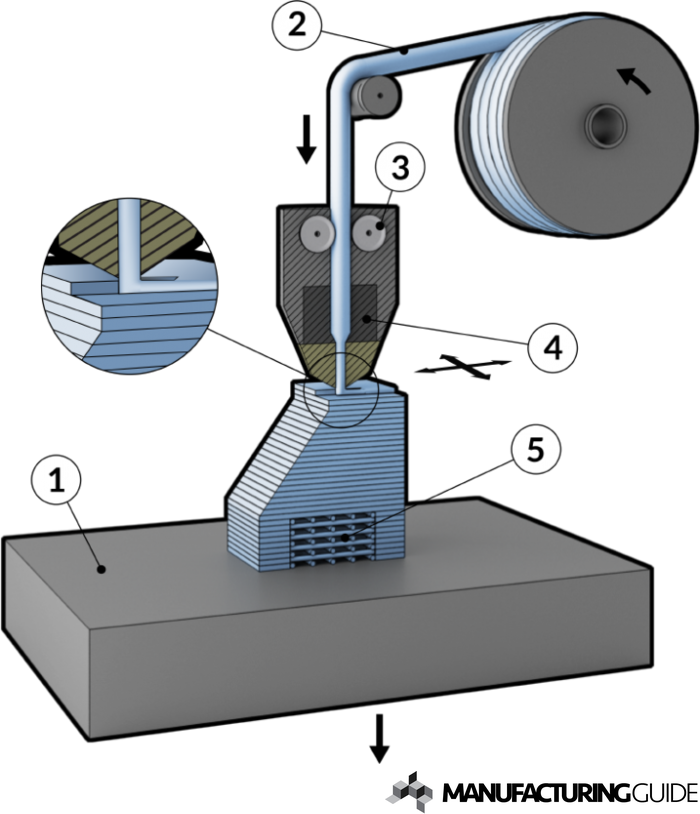

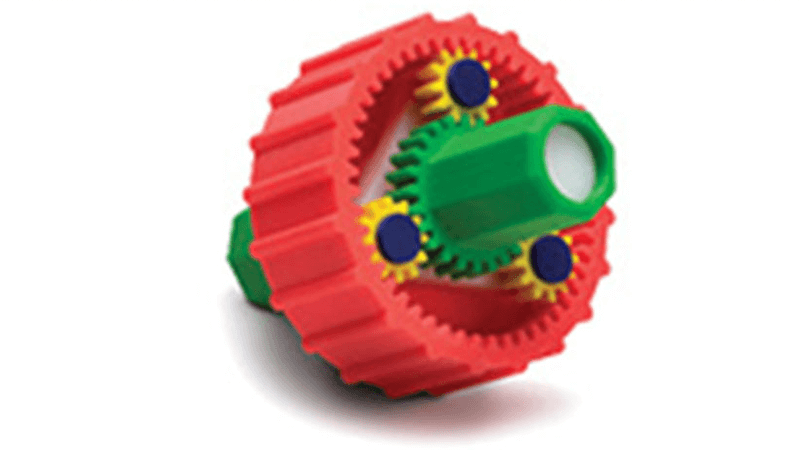

Fused Deposition Modeling Fdm 3d Printing Technology How It 43 Off This survey provides a thorough examination of fused deposition mod eling (fdm), a prevalent 3d printing technology known f or its accessibility an d versatility. fdm has emerged as a. Fused deposition modeling (fdm) or fused filament fabrication (fff) is the most widely adopted 3d printing technology. in this explanation, we will delve into the origins of this technology and how it operates. Explore the world of fused deposition modeling (fdm), the most accessible and versatile 3d printing technology. this comprehensive guide delves into its principles, applications, materials, advantages, and how to optimize your prints for superior results. Fused deposition modeling (also known as fdm ®) is the most widely used additive manufacturing technique known for its extensive material selection, print accuracy, repeatability, and durability. Fused deposition modeling (fdm) has emerged as a transformative force in the realm of additive manufacturing, providing a cost effective and versatile solution for creating three dimensional objects. developed by scott crump in the late 1980s, fdm has evolved into a widely adopted 3d printing technology with applications across various industries. Fused deposition modeling (fdm) is an extrusion based 3d printing technology. the build materials used in fdm are thermoplastic polymers and come in a filament form. in fdm, a part is manufactured by selectively depositing melted material layer by layer in a path defined by the cad model.

Fused Deposition Modeling Fdm Find Suppliers Processes Material Explore the world of fused deposition modeling (fdm), the most accessible and versatile 3d printing technology. this comprehensive guide delves into its principles, applications, materials, advantages, and how to optimize your prints for superior results. Fused deposition modeling (also known as fdm ®) is the most widely used additive manufacturing technique known for its extensive material selection, print accuracy, repeatability, and durability. Fused deposition modeling (fdm) has emerged as a transformative force in the realm of additive manufacturing, providing a cost effective and versatile solution for creating three dimensional objects. developed by scott crump in the late 1980s, fdm has evolved into a widely adopted 3d printing technology with applications across various industries. Fused deposition modeling (fdm) is an extrusion based 3d printing technology. the build materials used in fdm are thermoplastic polymers and come in a filament form. in fdm, a part is manufactured by selectively depositing melted material layer by layer in a path defined by the cad model.

Fused Deposition Modeling Fdm Overview Fused deposition modeling (fdm) has emerged as a transformative force in the realm of additive manufacturing, providing a cost effective and versatile solution for creating three dimensional objects. developed by scott crump in the late 1980s, fdm has evolved into a widely adopted 3d printing technology with applications across various industries. Fused deposition modeling (fdm) is an extrusion based 3d printing technology. the build materials used in fdm are thermoplastic polymers and come in a filament form. in fdm, a part is manufactured by selectively depositing melted material layer by layer in a path defined by the cad model.