Flat Ribbon Cable Production Process Ecocables Splicing a ribbon cable is a relatively straightforward process that requires some basic tools and materials. by following the steps outlined in this article, you can successfully splice a ribbon cable and extend its length or repair a damaged section. Splicing a ribbon cable may seem like a straightforward task, but it requires careful planning and execution to ensure a reliable and efficient connection. we will discuss the different types of ribbon cable splicing techniques, including soldering, insulation displacement connectors (idcs), and crimping.

30 Pin Ribbon Cable Ecocables In this guide, we will take you through the process of stripping a thin ribbon cable, providing you with clear instructions and helpful tips along the way. whether you need to repair a cable or modify it for a specific project, knowing how to strip a thin ribbon cable is an essential skill for any electronics enthusiast or technician. When it comes to splitting a ribbon cable, there are several techniques you can employ to ensure a safe and clean process. one effective method is using a sharp utility knife or a pair of fine scissors to carefully separate the individual strands of the cable. How to process a ribbon cable. stripping a ribbon cable should be done with utmost care such that they do not sustain bruises or a total disconnection in the process. follow the following steps to successfully strip a ribbon cable. 1. cut the jacket open. ribbon cables are usually enclosed in a jacket which makes them come in handy. Simply stack the fibers in color sequence and add an adhesive to create the ribbon matrix. [ ] ribbon units can be completed in less than 3 minutes, including adhesive drying time. [ ] large fiber count cables can be spliced in one day.

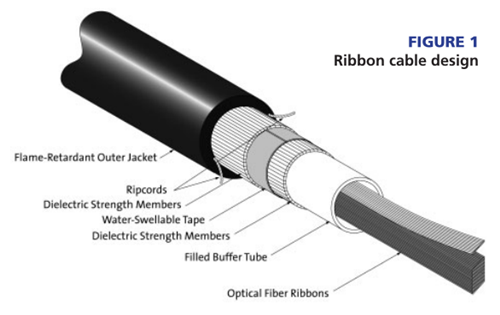

Ribbon Cable Design Fiber Optic Cables Solutions How to process a ribbon cable. stripping a ribbon cable should be done with utmost care such that they do not sustain bruises or a total disconnection in the process. follow the following steps to successfully strip a ribbon cable. 1. cut the jacket open. ribbon cables are usually enclosed in a jacket which makes them come in handy. Simply stack the fibers in color sequence and add an adhesive to create the ribbon matrix. [ ] ribbon units can be completed in less than 3 minutes, including adhesive drying time. [ ] large fiber count cables can be spliced in one day. Quality control technician, tia kirk demonstrates how to prepare the ends of an optical fiber ribbon cable for splicing. the product featured is our single tube single armor optical fiber. This article will guide you through the process of soldering ribbon cables effectively, ensuring strong and durable connections. ribbon cables, also known as flat cables, consist of multiple parallel conductors enclosed in a flat plastic or pvc jacket. 1.1 this procedure describes the sheath removal and stripping 8 and 12 fiber ribbon fiber optic interconnect cables. 1.2 corning cable systems ribbon interconnect cables are lightweight, flame retardant cables designed for high performance transmission of digital and analog signals in process control, computer and video applications (figure 1). This video shows how to operate rs 330a to cut and strip &split flat ribbon cable. the cylinder part is used to split ribbon cable. the main machine can cut and strip insulation. with lcd.