Defect Detection Technica Industrial Ai Defect detection in additive manufacturing refers to the evaluation of collected industrial images and the identification of parts that cause anomalies to optim. Automatic visual inspection using machine learning based methods plays a key role in achieving zero defect policies in industry. research on anomaly detection approaches is constrained by the availability of datasets that represent complex defect appearances and imperfect imaging conditions, which are typical to industrial processes. recent benchmarks indicate that most publicly available.

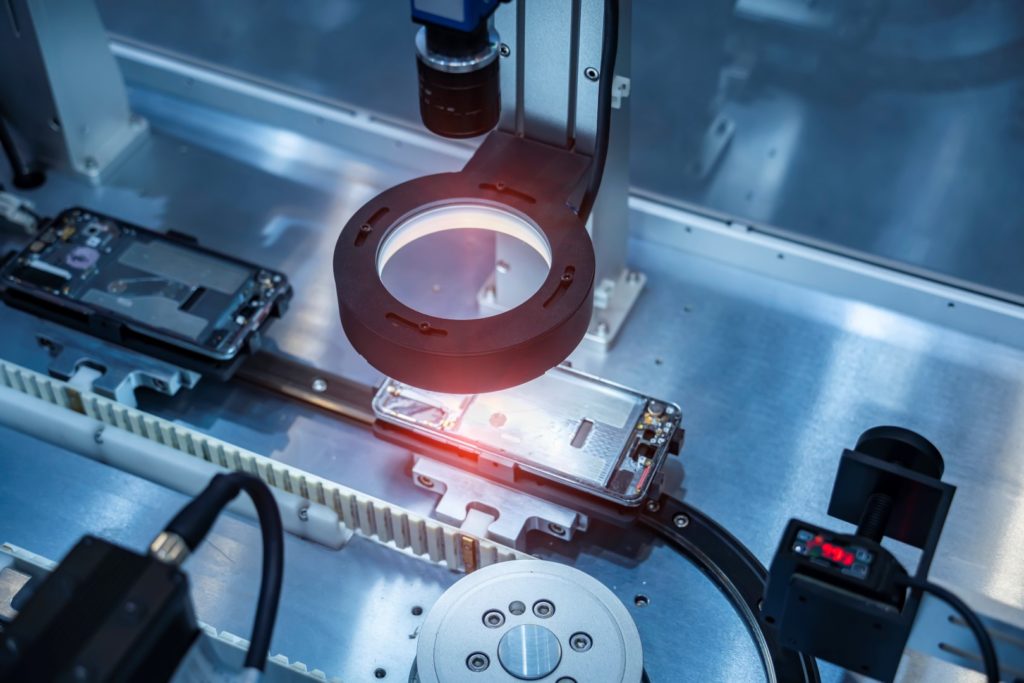

Ai Powered Visual Defect Detection Vanti The project leverages a deep learning framework to automate real time flaw detection in the manufacturing process. it harnesses extensive datasets of annotated images to discern complex defect patterns. this integrated system seamlessly fits into production workflows, thereby boosting efficiency and elevating product quality. A universal machine learning solution for automated quality inspection and defect detection on manufacturing lines, utilizing object detection models (yolo) and computer vision (opencv) to classify defective and non defective materials, boosting accuracy and efficiency. Ai based defect detection relies on deep learning to replicate the decision making process of a skilled inspector. advanced systems must identify a wide range of defects, distinguish between critical and non critical flaws, and incorporate data driven insights from previous inspections. In industrial settings, surface defects on steel can significantly compromise its service life and elevate potential safety risks. traditional defect detection methods predominantly rely on manual inspection, which suffers from low efficiency and high costs. although automated defect detection approaches based on convolutional neural networks(e.g., mask r cnn) have advanced rapidly, their.

Ai Defect Detection Types Advantages How To Implement It Ai based defect detection relies on deep learning to replicate the decision making process of a skilled inspector. advanced systems must identify a wide range of defects, distinguish between critical and non critical flaws, and incorporate data driven insights from previous inspections. In industrial settings, surface defects on steel can significantly compromise its service life and elevate potential safety risks. traditional defect detection methods predominantly rely on manual inspection, which suffers from low efficiency and high costs. although automated defect detection approaches based on convolutional neural networks(e.g., mask r cnn) have advanced rapidly, their. In recent years, with the rapid development of deep learning, computer vision technology based on convolutional neural network (cnn) is widely used in industrial fields. at present, surface defect detection by machine vision is one of the most mature. Our findings suggest these techniques can significantly contribute to the goals of lean manufacturing by enhancing defect detection and optimizing quality control processes. future research should continue to refine ai model integration and scalability within varied manufacturing environments, emphasizing adaptability and efficiency to support. Harness the power of low power ai inference with polarfire soc video kit and vectorblox sdk today! at spanidea, we specialize in delivering cutting edge ai algorithm models tailored for a wide range of industrial applications, including pcb inspection, defect detection, predictive maintenance and smart automation. With genai, manufacturing companies can conduct continuous defect monitoring and root cause analysis (rca) for real time quality control to ensure a more efficient and reliable production process. you’ve likely encountered several case studies where ai powered vision systems are used for defect detection and quality control.

Ai Powered Defect Detection For Textile And Fabric Manufacturing In recent years, with the rapid development of deep learning, computer vision technology based on convolutional neural network (cnn) is widely used in industrial fields. at present, surface defect detection by machine vision is one of the most mature. Our findings suggest these techniques can significantly contribute to the goals of lean manufacturing by enhancing defect detection and optimizing quality control processes. future research should continue to refine ai model integration and scalability within varied manufacturing environments, emphasizing adaptability and efficiency to support. Harness the power of low power ai inference with polarfire soc video kit and vectorblox sdk today! at spanidea, we specialize in delivering cutting edge ai algorithm models tailored for a wide range of industrial applications, including pcb inspection, defect detection, predictive maintenance and smart automation. With genai, manufacturing companies can conduct continuous defect monitoring and root cause analysis (rca) for real time quality control to ensure a more efficient and reliable production process. you’ve likely encountered several case studies where ai powered vision systems are used for defect detection and quality control.