Lean And Agile Supply Chains Part 2 The Supply Chain Consulting Group In this post, we'll compare two supply chain methods: agile vs lean. ready to transform your supply chain? we’ll see how each originated, their applications to the supply chain, and their benefits. let’s start by learning where agile began. software development in the early days was problematic. Lean and agile are popular supply chain approaches, each with its own advantages and drawbacks. lean focuses on waste reduction, inventory optimization and continuous improvement while agile emphasizes flexibility and responsiveness to changing demands.

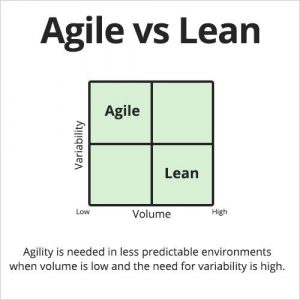

Agile Vs Lean Is There A Difference Each approach offers distinct advantages and caters to different business environments. a lean supply chain focuses on efficiency, cost reduction, and minimizing waste. on the other hand, an agile supply chain emphasizes flexibility and responsiveness, particularly in industries where demand is highly variable. Comparing lean and agile supply chains. lean supply chains focus on efficiency and minimizing costs by reducing waste and optimizing inventory. in contrast, agile supply chains emphasize responsiveness and adaptability to changing market demands. the decision to adopt a lean or agile approach hinges on factors such as demand variability. Agile supply chain vs lean supply chain has different approaches to managing and optimizing the supply chain process. lean methodology focuses on minimizing waste and increasing efficiency. it involves identifying and eliminating non value added activities, streamlining processes, and reducing excess inventory. Lean supply chains typically rely on just in time (jit) delivery and a continuous flow of goods through the supply chain. this approach is suited for businesses that have stable demand.

Lean Vs Agile Supply Chain Management Procurement Pro Agile supply chain vs lean supply chain has different approaches to managing and optimizing the supply chain process. lean methodology focuses on minimizing waste and increasing efficiency. it involves identifying and eliminating non value added activities, streamlining processes, and reducing excess inventory. Lean supply chains typically rely on just in time (jit) delivery and a continuous flow of goods through the supply chain. this approach is suited for businesses that have stable demand. A lean supply chain is cost conscious and efficient, but it won’t be able to respond to new demands quickly. on the other hand, an agile supply chain is highly adaptable, but it can become hard to control and predict. The primary difference between agile and lean supply chains lies in their approach to flexibility and efficiency. agile supply chains prioritize flexibility and responsiveness, making them suitable for dynamic and unpredictable markets. They are well known as the agile supply chain and lean supply chain. which direction is better for your business? how to designate it? keep an eye on the main differences to find out. what is lean supply chain? the lean supply chain is dedicated to decreasing prices and waste. this system is oriented to fruitful and rational operations. Comparing agile supply chain and lean principles. when comparing lean vs agile, we examined speed and iteration, putting customers first, the role of discipline, production planning, and inventory control. speed and iteration. both agile and lean are quite similar in this regard.