Loading And Registering Paper How To Coated Synthetic Sheet Feed Air Assist

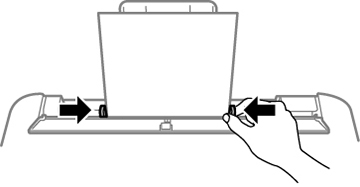

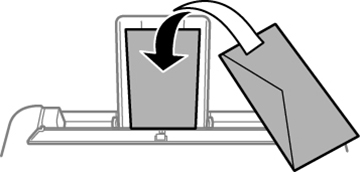

Loading Paper In The Sheet Feeder Paper subjected to an increase in temperature or a decrease in relative humidity will shrink (become tight edged) around the edges while the center remains its original size. If you load paper when only a few sheets of paper remain in the tray, multiple sheet feeding may occur. remove any remaining paper, stack them with the new sheets of paper, and then fan the entire stack before loading it into the tray.

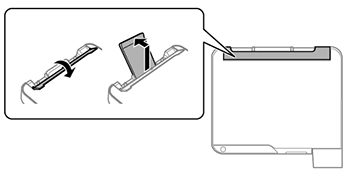

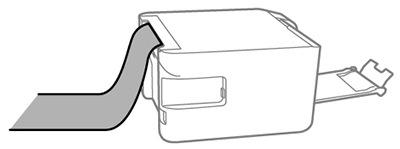

Loading Paper In The Sheet Feeder Before creating a printer profile, load the papers in a tray and register them. (refer to basic replenishing of paper.). Each sheet is fed from the paper source, transported vertically up the machine, then fed to the registration rollers and development section. sometimes a shorter, straight path runs from the by pass tray, this can be used to handle paper stocks that cannot run through the main paper path. All presses are composed of four basic units: feeder, registration, printing, and delivery. it is important that you understand the process a sheet of paper goes through in its trip from the infeed pile through the registration system to the printing unit and finally to the delivery pile. Feeding: an automated mechanism (using suction cups, friction rollers, or air pressure) separates and picks up one sheet at a time from the stack. registration: the sheet is precisely aligned (registered) to ensure the image is printed in the exact correct position on every sheet.

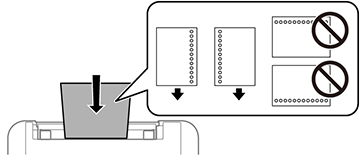

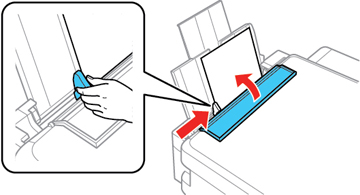

Loading Paper In The Sheet Feeder All presses are composed of four basic units: feeder, registration, printing, and delivery. it is important that you understand the process a sheet of paper goes through in its trip from the infeed pile through the registration system to the printing unit and finally to the delivery pile. Feeding: an automated mechanism (using suction cups, friction rollers, or air pressure) separates and picks up one sheet at a time from the stack. registration: the sheet is precisely aligned (registered) to ensure the image is printed in the exact correct position on every sheet. Learn how to register the size and type of paper loaded into the pixma pro 200. How to video detailing how to load and register certain types of paper using the multi purpose tray. If multiple pages feed at once, remove the paper, fan the edges to separate the sheets, and reload it. if multiple pages continue to feed at once, turn on the paper feed assist mode setting in the setup > system administration > printer settings menu.

Loading Paper In The Sheet Feeder Learn how to register the size and type of paper loaded into the pixma pro 200. How to video detailing how to load and register certain types of paper using the multi purpose tray. If multiple pages feed at once, remove the paper, fan the edges to separate the sheets, and reload it. if multiple pages continue to feed at once, turn on the paper feed assist mode setting in the setup > system administration > printer settings menu.

Loading Paper In The Sheet Feeder If multiple pages feed at once, remove the paper, fan the edges to separate the sheets, and reload it. if multiple pages continue to feed at once, turn on the paper feed assist mode setting in the setup > system administration > printer settings menu.

Loading Paper In The Sheet Feeder

Comments are closed.