Noise Reduction Rem Surface Engineering

Rem Surface Engineering Home Facebook Rem’s isf ® technologies are able to reduce structure borne noise caused by the friction between metal to metal contact parts. this reduction in noise is achieved by the unique characteristics of the surface that rem’s isotropic superfinishing surfaces generate. When applied to the metal components, rem’s revolutionary isf® process produces a unique isotropic surface condition. the isotrpoic superfinish process significantly reduces wear in parts made of these materials. rem is always open to working with new materials and alloys.

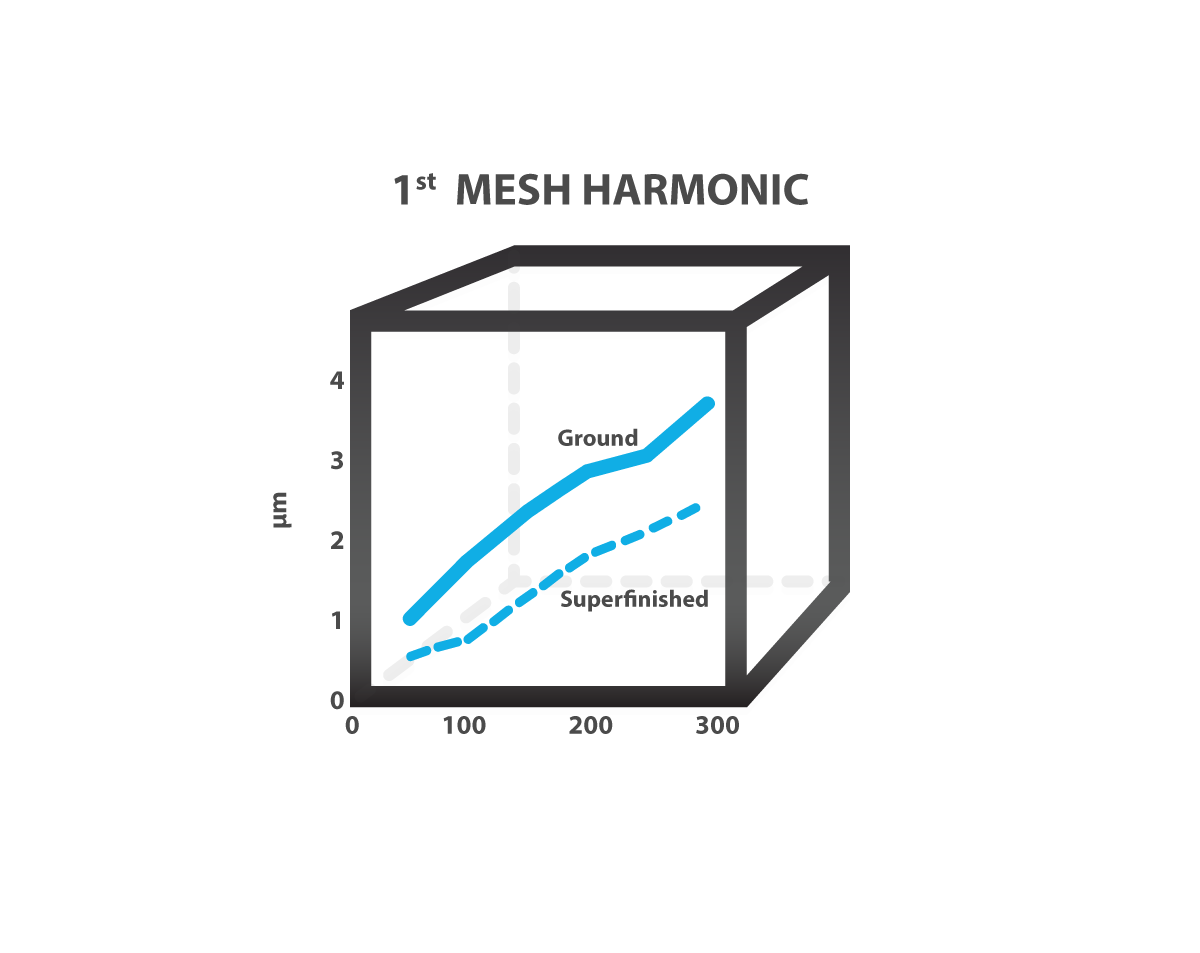

Rem Surface Engineering On Linkedin Rem Surface Engineering Rem Tackling ev noise reduction the advent and ever increasing demand for the quiet electric vehicle is driving the industry to reduce transmission error and manufacture higher quality gears. The first time i heard of vibro acoustic noise was around 2001 when dr. don houser of ohio state university asked rem to participate in a research effort to monitor the frictional noise variations between ground and superfinished gears, as well as the influence of lubricant viscosity. The overarching theme from the sponsor feedback portion of the meeting was noise reduction associated with electric vehicle drivetrains. electric vehicles usually require reduction gears, and even multispeed geared transmissions, to achieve the appropriate road speeds. The extreme isf process can remove the extreme surface roughness and surface near surface defects of metal am components, improving dynamic fatigue life and corrosion resistance while improving flow properties by reducing turbulence and pressure drop.

History Of Rem Surface Engineering Proudly Serving Partners For 60 Years The overarching theme from the sponsor feedback portion of the meeting was noise reduction associated with electric vehicle drivetrains. electric vehicles usually require reduction gears, and even multispeed geared transmissions, to achieve the appropriate road speeds. The extreme isf process can remove the extreme surface roughness and surface near surface defects of metal am components, improving dynamic fatigue life and corrosion resistance while improving flow properties by reducing turbulence and pressure drop. Both the isf process and the rapid isf process are proven to be effective in delivering low roughness surfaces while maintaining component geometry and contact pattern without increasing noise, harshness, or vibration (nvh) across all common gear design variants (spur, helical, and spiral bevel). Our extreme isf process enabled the uniform removal of ~400 µm of surface material, reducing surface roughness and hot wall thickness, and extending the nozzle's fatigue life. Die isf ® verfahren von rem sind in der lage, den körperschall zu reduzieren, der durch die reibung zwischen den metall zu metall kontaktteilen entsteht. diese geräuschreduzierung wird durch die einzigartigen eigenschaften der isotropen superfinish oberflächen von rem erreicht. However, the industry faces challenges as it seeks to move into new and more challenging applications. poor surface finish and limited fatigue life are two of the largest challenges present in as printed metal am components. rem’s extreme isf ® process technologies address both of these challenges.

Noise Reduction Rem Surface Engineering Both the isf process and the rapid isf process are proven to be effective in delivering low roughness surfaces while maintaining component geometry and contact pattern without increasing noise, harshness, or vibration (nvh) across all common gear design variants (spur, helical, and spiral bevel). Our extreme isf process enabled the uniform removal of ~400 µm of surface material, reducing surface roughness and hot wall thickness, and extending the nozzle's fatigue life. Die isf ® verfahren von rem sind in der lage, den körperschall zu reduzieren, der durch die reibung zwischen den metall zu metall kontaktteilen entsteht. diese geräuschreduzierung wird durch die einzigartigen eigenschaften der isotropen superfinish oberflächen von rem erreicht. However, the industry faces challenges as it seeks to move into new and more challenging applications. poor surface finish and limited fatigue life are two of the largest challenges present in as printed metal am components. rem’s extreme isf ® process technologies address both of these challenges.

Rem Surface Engineering Announces Growth To Rrg Team Rem Surface Die isf ® verfahren von rem sind in der lage, den körperschall zu reduzieren, der durch die reibung zwischen den metall zu metall kontaktteilen entsteht. diese geräuschreduzierung wird durch die einzigartigen eigenschaften der isotropen superfinish oberflächen von rem erreicht. However, the industry faces challenges as it seeks to move into new and more challenging applications. poor surface finish and limited fatigue life are two of the largest challenges present in as printed metal am components. rem’s extreme isf ® process technologies address both of these challenges.

Rem Builders Present Noise Reduction Measures

Comments are closed.