Optimize Gas Turbine Performance Using Acoustic Simulation Software

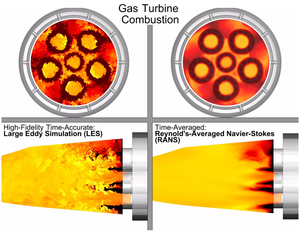

Optimize Gas Turbine Performance Using Acoustic Simulation Software Tuned for performance autonomous tuning is a gas turbine performance software that automatically tunes gas turbines for emissions compliance and ideal performance based upon changes in ambient temperature, fuel properties and degradation. In this paper, the acoustic numerical model of a heavy duty gas turbine combustor is established and its acoustic characteristics are studied using ansys simulation software.

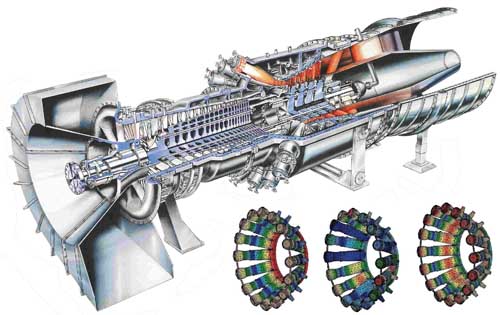

Optimize Gas Turbine Performance Using Acoustic Simulation Software Design optimization: engineers use aeroacoustic simulation to assess the acoustic impact of design changes and to optimize structures for reduced noise output, enhancing both performance and compliance with noise regulations. Ansys offers a best in class multiphysics simulation solution for all gas turbine modules from inlet to exhaust. the end to end solution helps engine manufacturers increase safety, performance and efficiency while reducing emissions, noise, weight and maintenance cost. The study aims to identify the factors that cause degradation in gas turbine performance and provide recommendations to improve gas turbine performance. this paper is divided into four parts: introduction, materials, methodology, and results. Ansys offers an end to end simulation solution that enables engineers to design, optimize and test their next generation gas turbines in a multidisciplinary virtual design space.

136 2 Gas Turbine Simulation The study aims to identify the factors that cause degradation in gas turbine performance and provide recommendations to improve gas turbine performance. this paper is divided into four parts: introduction, materials, methodology, and results. Ansys offers an end to end simulation solution that enables engineers to design, optimize and test their next generation gas turbines in a multidisciplinary virtual design space. With using advanced and specilized cfd tools such as avl fire, siemens star ccm , ansys fluent and converge, enteknograte engineers can accurately predict important kinetically limited gas turbine phenomena such as ignition, flashback, and lean blow off. This study presents a novel online monitoring system that utilizes acoustic emission (ae) signals to detect and classify normal and faulty operating conditions of a gas turbine. We address this challenge by presenting a data driven approach that uses multiple probabilistic surrogate models derived from gaussian process regression to automatically select optimal combustor designs from a large parameter space, requiring only a few experimental data points.

Ge And Cascade Optimize Gas Turbine Simulation With using advanced and specilized cfd tools such as avl fire, siemens star ccm , ansys fluent and converge, enteknograte engineers can accurately predict important kinetically limited gas turbine phenomena such as ignition, flashback, and lean blow off. This study presents a novel online monitoring system that utilizes acoustic emission (ae) signals to detect and classify normal and faulty operating conditions of a gas turbine. We address this challenge by presenting a data driven approach that uses multiple probabilistic surrogate models derived from gaussian process regression to automatically select optimal combustor designs from a large parameter space, requiring only a few experimental data points.

Gas Turbine Simulation Program Free Telmsa We address this challenge by presenting a data driven approach that uses multiple probabilistic surrogate models derived from gaussian process regression to automatically select optimal combustor designs from a large parameter space, requiring only a few experimental data points.

Comments are closed.