Pin On Disk Testing For this reason, we have developed a pin on disc tribometer based on the open hardware approach, which can be completely additively manufactured by fused filament fabrication. in addition to presenting the customizable measurement system, we investigated the measurement capability using 50 repeated measurements on two different tribological. Pin on disk (pod) is essentially a materials tribology test that is frequently used to screen materials rather than whole tkr systems. because it is only marginally within the scope of the chapter, this category of tests will be only briefly visited here to highlight special considerations required for tkr testing applications.

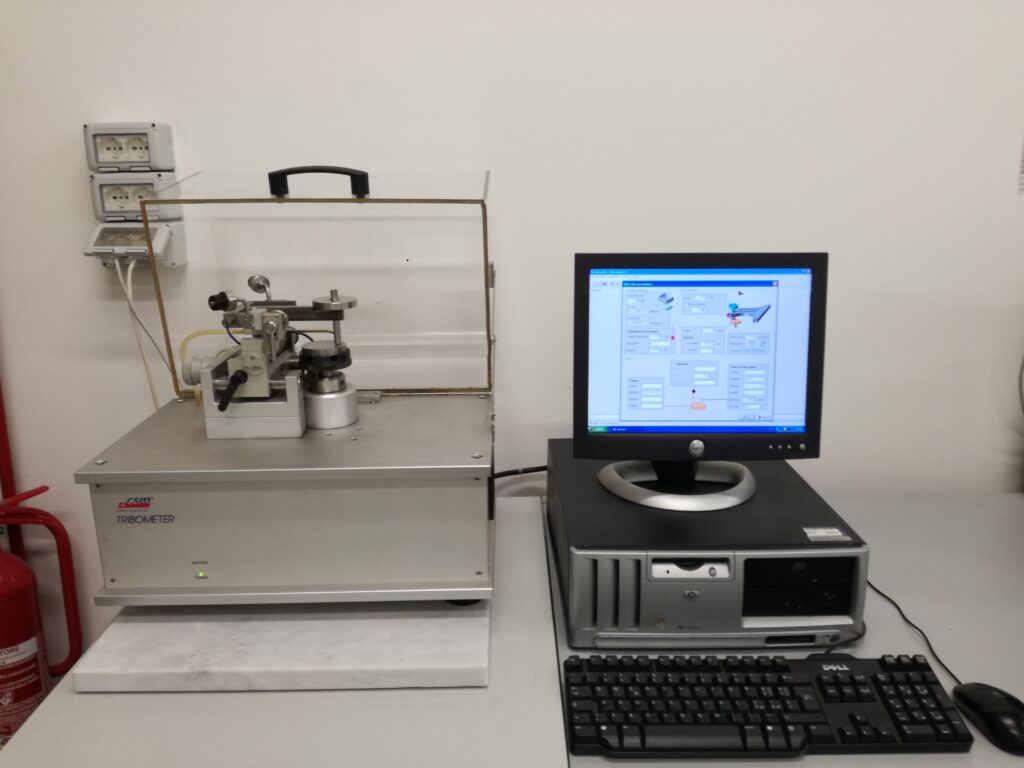

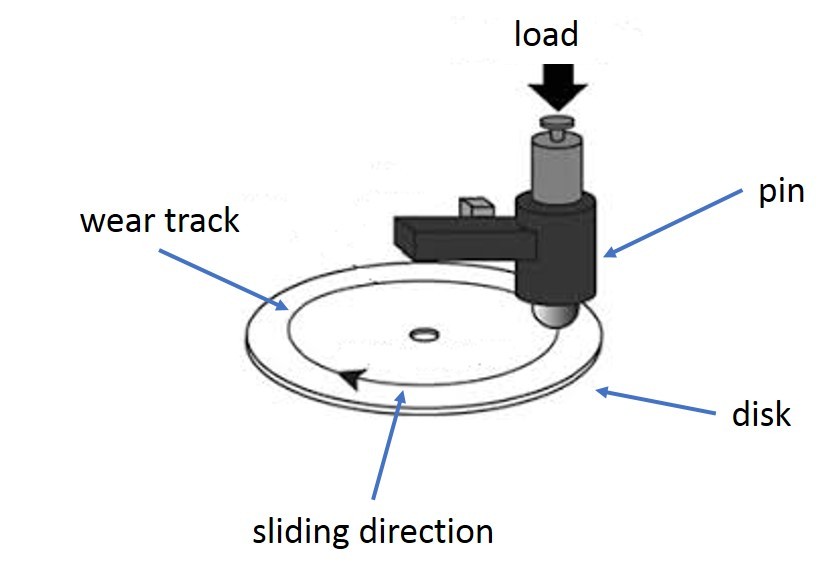

Pin On Disk Tribometer Metallurgical Testing Laboratory In order to investigate the sensitivity of a predicted stribeck curve we studied the macroscopic pin shape and its microscopic roughness in a simplified digital twin of a pin on disc tribometer. the numerical model consists of the homogenized reynolds equation with mass conserving cavitation, the boundary element method and the contact. Tribometer trb s ee 0000 is a pin on disc tribometer equipped with its own workstation (computer, screen and electronic control), which is used for materials' or coatings' friction coefficient determination, depending on the time of contact speidiena, speed, temperature, moisture and lubrication conditions. 1. The most common test rigs employ a pin or a ball pressed against a disc or plate surface (pin on disc or ball on disc, pin on plate). the pin on disc tribometer serves for the investigation and simulation of friction and wear processes under sliding conditions. it can be operated for solid friction without lubrication. Pin on disk, pin on ring, pin on flat, ball on flat tests are all similar to each other with the differences in the geometry of a specific tribometer and the pin. pin on disk test can be performed by various tribometers. rtec instruments offers a universal tribometer covering various standard tribological tests, including pin on disk test:.

Pin On Disk Test About Tribology The most common test rigs employ a pin or a ball pressed against a disc or plate surface (pin on disc or ball on disc, pin on plate). the pin on disc tribometer serves for the investigation and simulation of friction and wear processes under sliding conditions. it can be operated for solid friction without lubrication. Pin on disk, pin on ring, pin on flat, ball on flat tests are all similar to each other with the differences in the geometry of a specific tribometer and the pin. pin on disk test can be performed by various tribometers. rtec instruments offers a universal tribometer covering various standard tribological tests, including pin on disk test:. The pin on disk tribometer is used by labs all over the world for their material bench marking and materials development needs. this test method is a laboratory procedure for discerning the wear of materials during sliding using a pin on disk setup. materials are tested in dyads under typically non abrasive conditions. Pin on disk method is necessary to have a pair of samples. the rst will a pin with a round end which is perpendicularly located respect to the other sample material. the pin specimen commonly is a ball rigidly held. the test machine causes either the pin sample or the disk revolving about the center. therefore,. In 2016, researchers proposed the design of a completely computer controlled pin on disk type tribometer that measures the coefficient of friction by utilizing a three axis piezoelectric force sensor. the performance of the proposed tribometer is demonstrated with a case study that includes the measurement of friction and wear of a dry clutch [1]. The pin on disk device was developed using the engineering design process (edp) based on steps related to problem understanding and solution construction stages. the tribometer is composed of an aluminum structure, a cylindrical test chamber, a disk rotation control system, load cells for measuring normal and tangential forces, a disk position.

Pin On Disk Tribometer A Scheme Of Pin On Disk Assembly B Device Image The pin on disk tribometer is used by labs all over the world for their material bench marking and materials development needs. this test method is a laboratory procedure for discerning the wear of materials during sliding using a pin on disk setup. materials are tested in dyads under typically non abrasive conditions. Pin on disk method is necessary to have a pair of samples. the rst will a pin with a round end which is perpendicularly located respect to the other sample material. the pin specimen commonly is a ball rigidly held. the test machine causes either the pin sample or the disk revolving about the center. therefore,. In 2016, researchers proposed the design of a completely computer controlled pin on disk type tribometer that measures the coefficient of friction by utilizing a three axis piezoelectric force sensor. the performance of the proposed tribometer is demonstrated with a case study that includes the measurement of friction and wear of a dry clutch [1]. The pin on disk device was developed using the engineering design process (edp) based on steps related to problem understanding and solution construction stages. the tribometer is composed of an aluminum structure, a cylindrical test chamber, a disk rotation control system, load cells for measuring normal and tangential forces, a disk position.