Process Mapping In Lean Six Sigma Measure Phase

Lean Six Sigma Measure Phase Pdf The measure phase is about the baseline of the current process, data collection, validating the measurement system, and determining the process capability. multiple tools and concepts are available in the measure phase of six sigma. This video is about how to do detailed process mapping in the measure phase of lean six sigma. in this phase we write all the steps or processes that are currently involved in making.

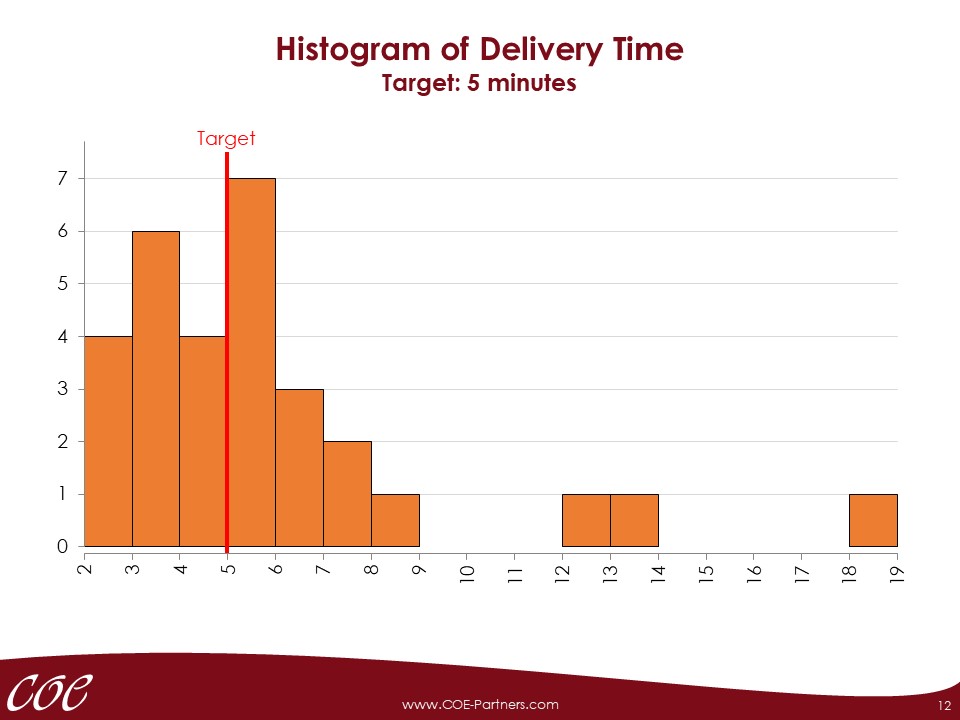

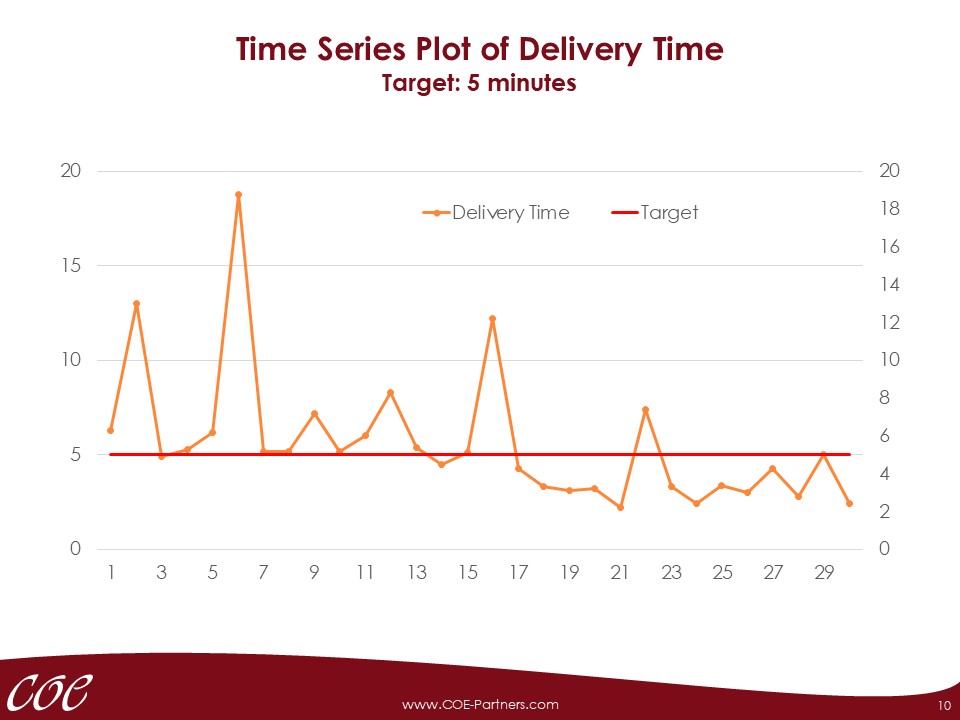

Measure Phase Collect Data For Lean Six Sigma Project Coe The first component in the measure phase is process mapping, which is a crucial tool for visualising and understanding how a process operates. process mapping allows you to identify the process flow, inputs and outputs, and the many steps involved. Detailed process map describes the step by step stream and conclusion within a course. this also provides foundation for representative training and orientation. Define is the first phase of the lean six sigma improvement process. during this phase the project team drafts a project charter, plots a high level map of the process and clarifies the needs of the process customers. In the lean six sigma measure phase, potential root causes for the problem will be determined, data for problem and potential root causes will be collected and the actual process performance will be established.

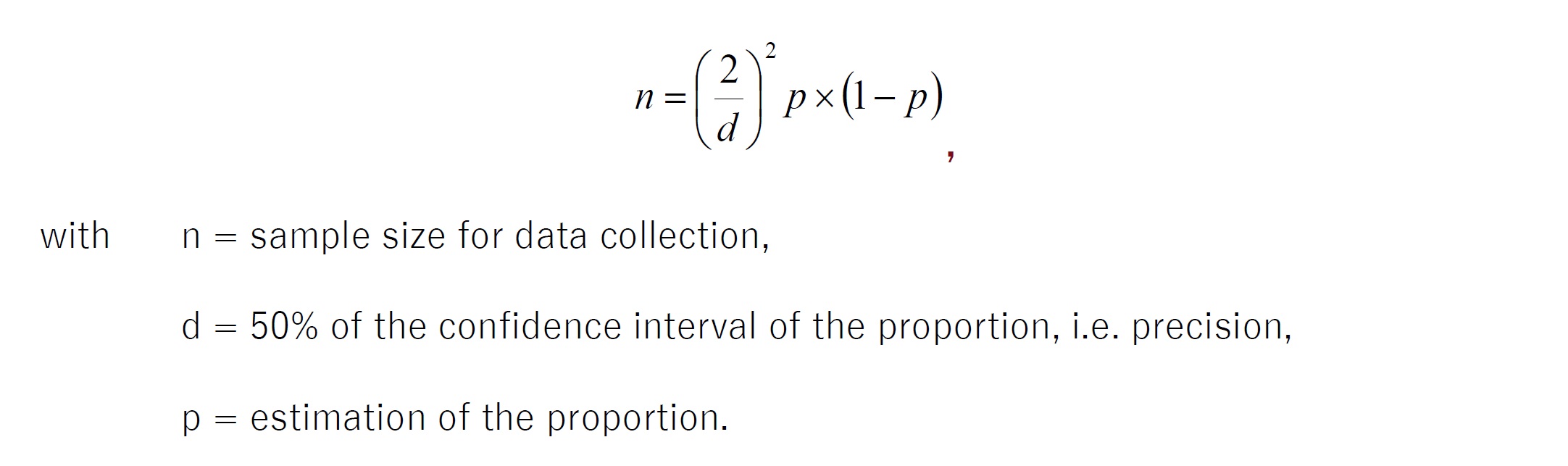

Measure Phase Collect Data For Lean Six Sigma Project Coe Define is the first phase of the lean six sigma improvement process. during this phase the project team drafts a project charter, plots a high level map of the process and clarifies the needs of the process customers. In the lean six sigma measure phase, potential root causes for the problem will be determined, data for problem and potential root causes will be collected and the actual process performance will be established. Utilize the process map and identify where the problem is occurring in the process steps. first, your team must establish the current state, or the “baseline” of the process before making any changes. the baseline becomes the standard against which any improvement is measured. Answer: in the measure phase of six sigma, important tools and techniques used include process mapping, data collection, measurement system analysis (msa), and statistical analysis. Map the process: detailed process mapping at this stage can help identify potential sources of variation and understand the process flow thoroughly. tools such as value stream mapping or detailed process flowcharts are often used. Learn what and how different types of process maps can be used.

Measure Phase Collect Data For Lean Six Sigma Project Coe Utilize the process map and identify where the problem is occurring in the process steps. first, your team must establish the current state, or the “baseline” of the process before making any changes. the baseline becomes the standard against which any improvement is measured. Answer: in the measure phase of six sigma, important tools and techniques used include process mapping, data collection, measurement system analysis (msa), and statistical analysis. Map the process: detailed process mapping at this stage can help identify potential sources of variation and understand the process flow thoroughly. tools such as value stream mapping or detailed process flowcharts are often used. Learn what and how different types of process maps can be used.

Measure Phase Collect Data For Lean Six Sigma Project Coe Map the process: detailed process mapping at this stage can help identify potential sources of variation and understand the process flow thoroughly. tools such as value stream mapping or detailed process flowcharts are often used. Learn what and how different types of process maps can be used.

Comments are closed.