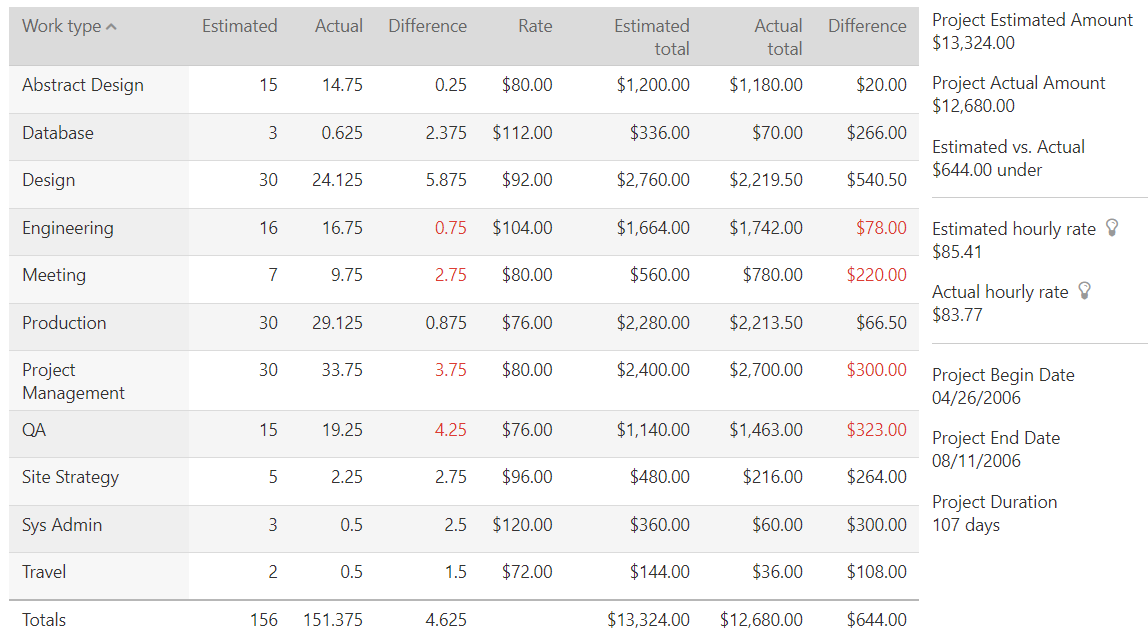

Tracking Time Against Project Estimates Intervals Features The factorial methods for estimating the total installed cost of a process plant are based on a combination of materials, labor and overhead cost components. project evaluation enables the technical and economic feasibility of a chemical process to be assessed using preliminary process design and economic evaluations. We estimate that between 2.6 million barrels b d and 4.9 million b d of refining capacity will come online over 2024–28. our analysis discusses only projects with reasonable expectations of coming online within the next four years, based on project announcements.

Refinery Project Pdf It explains how the investment cost for an oil & gas facility is estimated. after a short introduction, the 3 common methods of cost estimate are shown. common ratios, such as $ kg for equipment, pipe etc. are given. comments are most welcome (herve.baron@gmail ), which i will incorporate for the benefit of all. quantities?. Describes a method for comparing refinery project costs and attempts to establish an industry baseline against which investment costs for such projects can be compared. created date 3 6 2009 12:25:30 pm. Cost estimates, define project execution planning, and conduct profitability and financial analyses. decades of cooperation with top rated technology licensors and catalyst suppliers enable us to ensure an independent selection of the best technologies to meet specific project targets. Utilizing our refining knowledge base, comprehensive refinery database, and price forecasts, ihs markit models the competitiveness of >525 global operating refineries. refinery cost and margin analytics combines robust underlying data with visualization and analytical tools to provide an intuitive way to benchmark the competitive landscape of the.

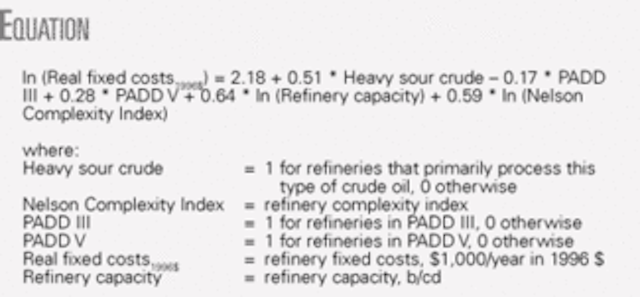

Method Estimates Us Refinery Fixed Costs Oil Gas Journal Cost estimates, define project execution planning, and conduct profitability and financial analyses. decades of cooperation with top rated technology licensors and catalyst suppliers enable us to ensure an independent selection of the best technologies to meet specific project targets. Utilizing our refining knowledge base, comprehensive refinery database, and price forecasts, ihs markit models the competitiveness of >525 global operating refineries. refinery cost and margin analytics combines robust underlying data with visualization and analytical tools to provide an intuitive way to benchmark the competitive landscape of the. Estimating cost of process projects are done using techniques ranging from conceptual (approximate, stochastic) methods to deterministic (detailed or definitive) methods. the quality accuracy of the cost estimate and its management determine whether the project will succeed or fail. We expect refining capacity to shrink by as much as 10% to 30% over the next ten years, depending on the region. historical energy efficiency projects or pinch studies are out of date. refreshing these analyses in the current environment can yield large cost saving opportunities. considering that various estimates put proven global. Oil refinery projects around the world. recently, we have been involved in a capital project (capex) benchmark cost study for a major consulting firm. the following are some general benchmarks from that study & earlier studies. production rate 25,000 barrels a day modularized oil refinery located in north africa:. This note describes a method for comparing refinery project costs and attempts to establish an industry baseline against which investment costs for such projects can be compared. the parametric methods it describes can be used to obtain rough cost estimates in the absence of detailed descriptive information (e.g., project characteristics) and.

Solved Refining Estimates May Be Necessary For A Number Of Chegg Estimating cost of process projects are done using techniques ranging from conceptual (approximate, stochastic) methods to deterministic (detailed or definitive) methods. the quality accuracy of the cost estimate and its management determine whether the project will succeed or fail. We expect refining capacity to shrink by as much as 10% to 30% over the next ten years, depending on the region. historical energy efficiency projects or pinch studies are out of date. refreshing these analyses in the current environment can yield large cost saving opportunities. considering that various estimates put proven global. Oil refinery projects around the world. recently, we have been involved in a capital project (capex) benchmark cost study for a major consulting firm. the following are some general benchmarks from that study & earlier studies. production rate 25,000 barrels a day modularized oil refinery located in north africa:. This note describes a method for comparing refinery project costs and attempts to establish an industry baseline against which investment costs for such projects can be compared. the parametric methods it describes can be used to obtain rough cost estimates in the absence of detailed descriptive information (e.g., project characteristics) and.

Refining Project Prediction Reference Class Forecasting Oil refinery projects around the world. recently, we have been involved in a capital project (capex) benchmark cost study for a major consulting firm. the following are some general benchmarks from that study & earlier studies. production rate 25,000 barrels a day modularized oil refinery located in north africa:. This note describes a method for comparing refinery project costs and attempts to establish an industry baseline against which investment costs for such projects can be compared. the parametric methods it describes can be used to obtain rough cost estimates in the absence of detailed descriptive information (e.g., project characteristics) and.