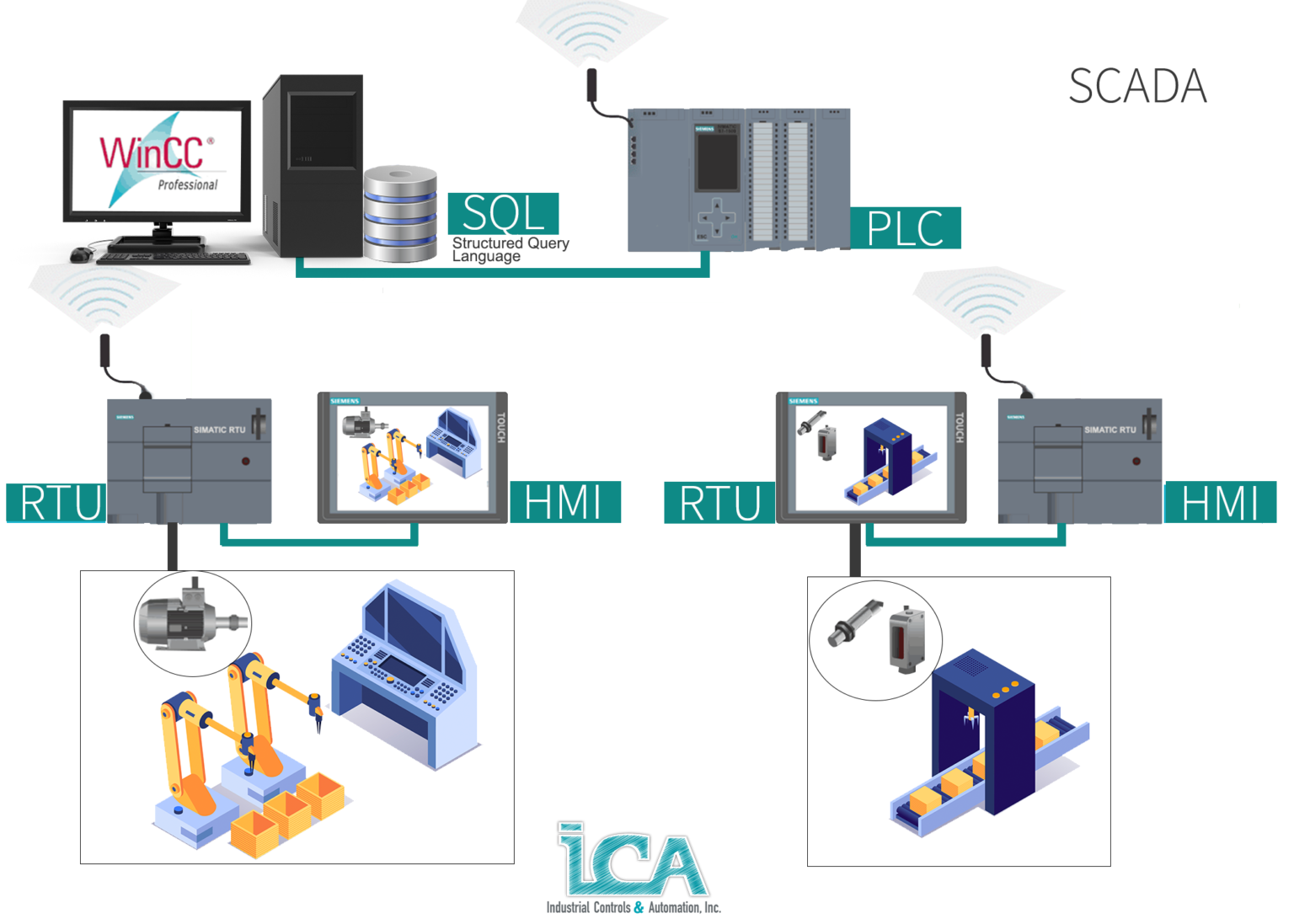

Scada In Manufacturing In a nutshell, the scada system is a collection of hardware and software components that allows the manufacturing units to perform specific functions. some of the important functions include to monitor and gather data in real time. Scada, or supervisory control and data acquisition, is a manufacturing system that uses real time monitoring and control of various processes and machinery. it is a centralized platform that collects and integrates data from various sources, such as sensors and control systems, to provide a holistic view of manufacturing operations.

Benefits Of Scada In Manufacturing Mikrodev What is scada? scada, short for supervisory control and data acquisition, is an industrial control system designed to monitor factory and plant operations either on site or from a remote location. a scada system is made up of both hardware devices and scada software that allow a user to control and monitor operations. a scada system can collect. Scada is a system of software and hardware elements that allows organizations to control and monitor industrial processes by directly interfacing with plant floor machinery and viewing real time data. using a scada system, industrial organizations can: control industrial processes and critical infrastructure locally or at remote locations. Applying a scada system in your facility can help decrease production waste and boost overall efficiency by providing useful production insights to operators and management. the information derived from a scada system can facilitate data driven decisions and lead to increased output, reduced costs, and greater control of your processes. Scada precisely controls every plant operation to ensure all systems run smoothly and meet productivity targets. scada tracks the number of units produced, & measures process values such as temperature, pressure, and humidity at various production phases. it also controls assembly line robots.

Scada Basics Ica Industrial Controls Automation Applying a scada system in your facility can help decrease production waste and boost overall efficiency by providing useful production insights to operators and management. the information derived from a scada system can facilitate data driven decisions and lead to increased output, reduced costs, and greater control of your processes. Scada precisely controls every plant operation to ensure all systems run smoothly and meet productivity targets. scada tracks the number of units produced, & measures process values such as temperature, pressure, and humidity at various production phases. it also controls assembly line robots. Additionally, scada systems can help manage inventory and energy consumption, improve maintenance, and more. they notify personnel when inventory is running low or machines need repairs, help optimize energy usage, and reduce costs. scada systems are also essential for troubleshooting by providing an overview of the entire system’s current. One of the most significant applications is in the manufacturing sector, where scada systems enable the automation of production lines. they can regulate the operation of machinery, manage assembly lines, and monitor product quality, leading to enhanced efficiency and productivity. Scada plays a critical role in manufacturing, enabling the automation of industrial processes. it allows operators to monitor and control the entire process from a central location, improving efficiency and quality. with scada, operators can monitor the status of equipment, track production metrics, and detect anomalies in real time. Scada accumulates and analyzes data while monitoring and controlling data sent from various devices and sensors. in addition to these features, alarms and security features may also be included. in addition, some data collected and accumulated is displayed is easy to understand graphics, enabling intuitive monitoring. scada's role.