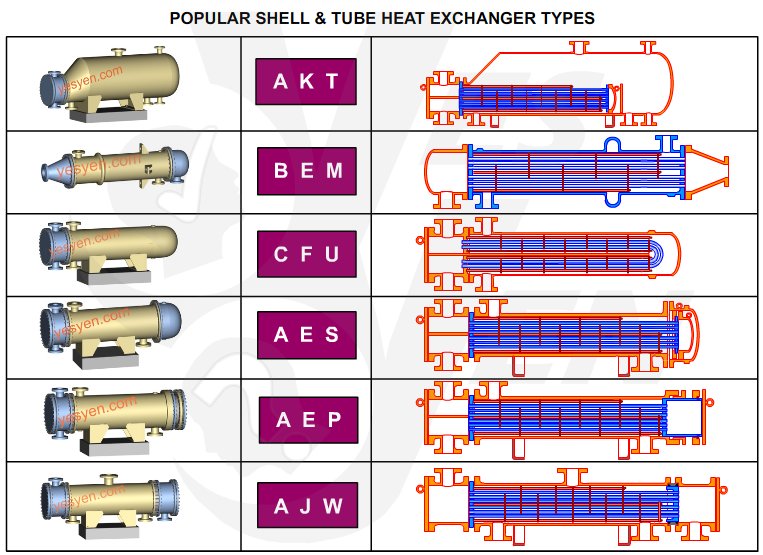

Shell And Tube Heat Exchanger Types Get to know the different types of shell and tube heat exchangers – fixed tube sheet, floating head, u tube, and kettle type – and their uses in industries like petrochemicals, power generation, and food processing. find out which type is best suited for your operational needs based on temperature, pressure, and fluid type. A shell and tube heat exchanger, in simple words, is a type of heat exchanger where the two working fluids exchange heat with the help of, as the name suggests, tubes and a shell. one of these is called the tube side fluid and the other is known as the shell side fluid.

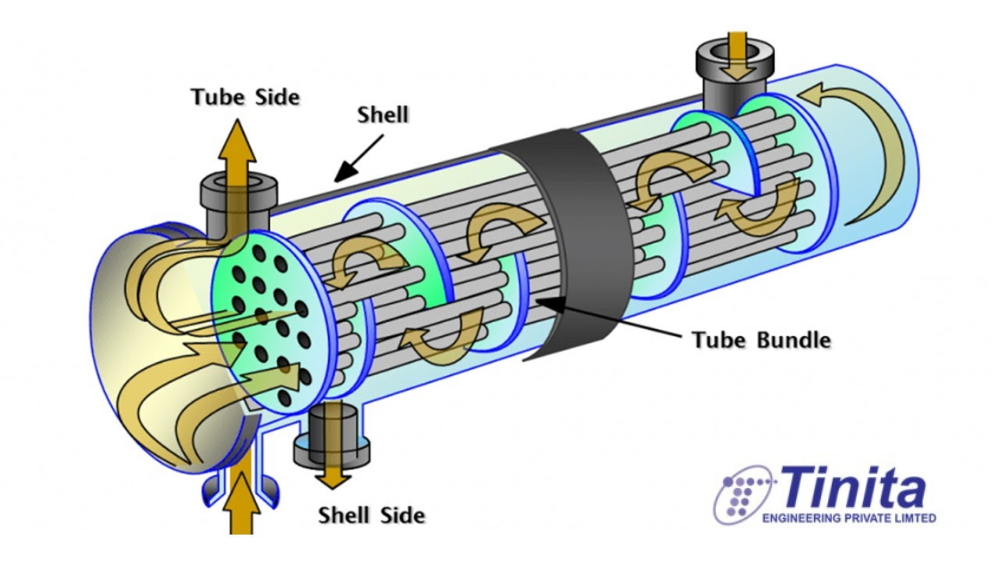

Shell And Tube Heat Exchanger What Is It Types Proces Vrogue Co As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. one fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. A shell and tube heat exchanger (sthe) is a type of heat exchanging device constructed using a large cylindrical enclosure, or shell, that has bundles of tubing compacted in its interior. the use and popularity of shell and tube heat exchangers is due to the simplicity of their design and efficient heat exchange rate. In the shell and tube heat exchanger process, one fluid flows through the tubes while the other fluid flows through the shell. the stipulations for the manufacture, design, and construction of shell and tube heat exchangers are outlined by the tubular exchangers manufacturers association (tema). Shell and tube heat exchangers transfer heat between two fluids (hot and cold) without allowing them to mix, relying on a design that maximizes thermal efficiency through conductive barriers. figure 2 illustrates the core components and flow paths of a typical shell and tube heat exchanger.

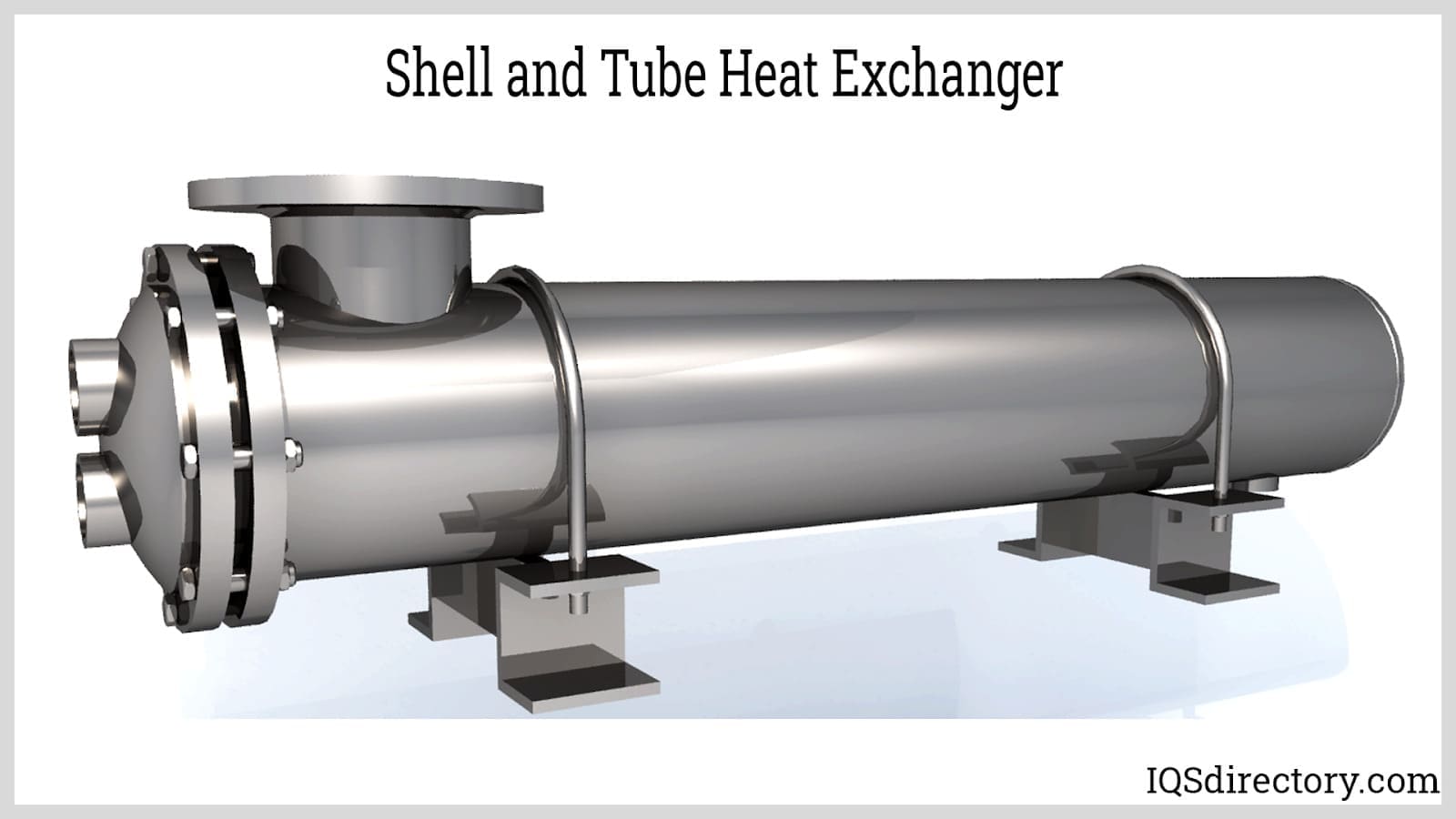

Shell And Tube Heat Exchanger Process Flow Diagram Vrogue Co In the shell and tube heat exchanger process, one fluid flows through the tubes while the other fluid flows through the shell. the stipulations for the manufacture, design, and construction of shell and tube heat exchangers are outlined by the tubular exchangers manufacturers association (tema). Shell and tube heat exchangers transfer heat between two fluids (hot and cold) without allowing them to mix, relying on a design that maximizes thermal efficiency through conductive barriers. figure 2 illustrates the core components and flow paths of a typical shell and tube heat exchanger. Shell and tube heat exchanger (sthe) is the most widely used heat exchanger and is among the most effective means of heat exchange. a shell and tube heat exchanger is a device where two working fluids exchange heat by thermal contact using tubes housed within a cylindrical shell. Shell and tube heat exchanger is also called a tube and tube heat exchanger. as the name suggests, this type of heat exchanger has an outer shell (a large pressure vessel) and a tube bundle. one fluid flow inside the tube while the other fluid flows over the tube. in this way, it transfers heat from one fluid to another. A heat exchanger is a device that transfers heat between two or more fluids without mixing them. these fluids can be liquids, gases, or a combination of both. heat exchangers are widely used in industries such as chemical processing, power generation, hvac, and food processing. common types of heat exchangers 1. shell and tube heat exchanger. What is a shell and tube heat exchanger? a shell and tube heat exchanger is a mechanical device used for transferring heat between two fluids, typically a hot fluid and a colder fluid while ensuring their separation. the exchanger consists of a cylindrical shell with multiple tubes running through it.

Shell Tube Heat Exchanger What Is It And What Is His Purpose Shell and tube heat exchanger (sthe) is the most widely used heat exchanger and is among the most effective means of heat exchange. a shell and tube heat exchanger is a device where two working fluids exchange heat by thermal contact using tubes housed within a cylindrical shell. Shell and tube heat exchanger is also called a tube and tube heat exchanger. as the name suggests, this type of heat exchanger has an outer shell (a large pressure vessel) and a tube bundle. one fluid flow inside the tube while the other fluid flows over the tube. in this way, it transfers heat from one fluid to another. A heat exchanger is a device that transfers heat between two or more fluids without mixing them. these fluids can be liquids, gases, or a combination of both. heat exchangers are widely used in industries such as chemical processing, power generation, hvac, and food processing. common types of heat exchangers 1. shell and tube heat exchanger. What is a shell and tube heat exchanger? a shell and tube heat exchanger is a mechanical device used for transferring heat between two fluids, typically a hot fluid and a colder fluid while ensuring their separation. the exchanger consists of a cylindrical shell with multiple tubes running through it.

Shell And Tube Heat Exchanger Manufacturer Pdf Pdf Host A heat exchanger is a device that transfers heat between two or more fluids without mixing them. these fluids can be liquids, gases, or a combination of both. heat exchangers are widely used in industries such as chemical processing, power generation, hvac, and food processing. common types of heat exchangers 1. shell and tube heat exchanger. What is a shell and tube heat exchanger? a shell and tube heat exchanger is a mechanical device used for transferring heat between two fluids, typically a hot fluid and a colder fluid while ensuring their separation. the exchanger consists of a cylindrical shell with multiple tubes running through it.

Shell And Tube Heat Exchanger Types Explained