Shell And Tube Types Heat Exchanger Artofit A shell and tube heat exchanger, in simple words, is a type of heat exchanger where the two working fluids exchange heat with the help of, as the name suggests, tubes and a shell. one of these is called the tube side fluid and the other is known as the shell side fluid. Each tema heat exchanger consists of following main parts: the front end stationary head (commonly referred to as “channel”); the tube bundle; the rear head and the shell. each part can be designed in several modifications, commonly referred to as “types”.

Shell And Tube Types Heat Exchanger Artofit Shell & tube heat exchangers are the most versatile type of heat exchangers. they are used in many alternative energy applications including ocean, thermal and geothermal. shell & tube heat exchangers provide relatively large ratios of heat transfer area to volume. they can be easily cleaned. By combining conduction, convection, and radiation, a good shell and tube heat exchanger can efficiently transfer the heat from one fluid to another. however, the design, parameters, configurations, and features play an important part in the entire process. Selection of heat transfer models and fouling coefficients for shell side and tube side. selection of heat exchanger tema layout and number of passes. specification of tube parameters size, layout, pitch and material. setting upper and lower design limits on tube length. Within this article we will cover the types of the heat exchangers for shell and tube. that is i tubes, u tube, kettles type and others. these are also divided according to the multiple passes and heat transfer coefficients. now we will try to understand about the exchanger in the details below.

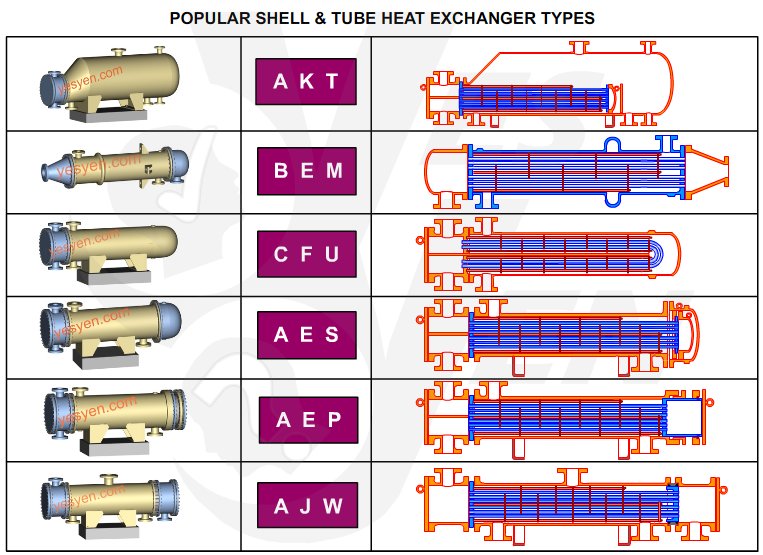

Shell And Tube Types Heat Exchanger Artofit Selection of heat transfer models and fouling coefficients for shell side and tube side. selection of heat exchanger tema layout and number of passes. specification of tube parameters size, layout, pitch and material. setting upper and lower design limits on tube length. Within this article we will cover the types of the heat exchangers for shell and tube. that is i tubes, u tube, kettles type and others. these are also divided according to the multiple passes and heat transfer coefficients. now we will try to understand about the exchanger in the details below. One of the most useful functions of tema is to provide a simple three letter system that completely defines all shell and tube exchangers with respect to exchanger type, stationary end head, rear end head and shell side nozzle configuration. this system is shown in figure 1. Amongst of all type of exchangers, shell and tube exchangers are most commonly used heat exchange equipment. the common types of shell and tube exchangers are: fixed tube sheet exchanger (non removable tube bundle): the simplest and cheapest type of shell and tube exchanger is with fixed tube sheet design. in this type of. Shell and tube heat exchangers are the most widely used and are among the most effective means of heat exchange. a shell and tube heat exchanger is a device where two working fluids exchange heat by thermal contact using tubes housed within a cylindrical shell. Understanding their design, functionality, and applications can help optimize operations and achieve efficiency in heat transfer processes. design of shell and tube heat exchangers. a shell and tube heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it.

Shell And Tube Types Heat Exchanger Artofit One of the most useful functions of tema is to provide a simple three letter system that completely defines all shell and tube exchangers with respect to exchanger type, stationary end head, rear end head and shell side nozzle configuration. this system is shown in figure 1. Amongst of all type of exchangers, shell and tube exchangers are most commonly used heat exchange equipment. the common types of shell and tube exchangers are: fixed tube sheet exchanger (non removable tube bundle): the simplest and cheapest type of shell and tube exchanger is with fixed tube sheet design. in this type of. Shell and tube heat exchangers are the most widely used and are among the most effective means of heat exchange. a shell and tube heat exchanger is a device where two working fluids exchange heat by thermal contact using tubes housed within a cylindrical shell. Understanding their design, functionality, and applications can help optimize operations and achieve efficiency in heat transfer processes. design of shell and tube heat exchangers. a shell and tube heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it.

Shell Tube Heat Exchanger Artofit Shell and tube heat exchangers are the most widely used and are among the most effective means of heat exchange. a shell and tube heat exchanger is a device where two working fluids exchange heat by thermal contact using tubes housed within a cylindrical shell. Understanding their design, functionality, and applications can help optimize operations and achieve efficiency in heat transfer processes. design of shell and tube heat exchangers. a shell and tube heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it.

Shell And Tube Heat Exchanger Types