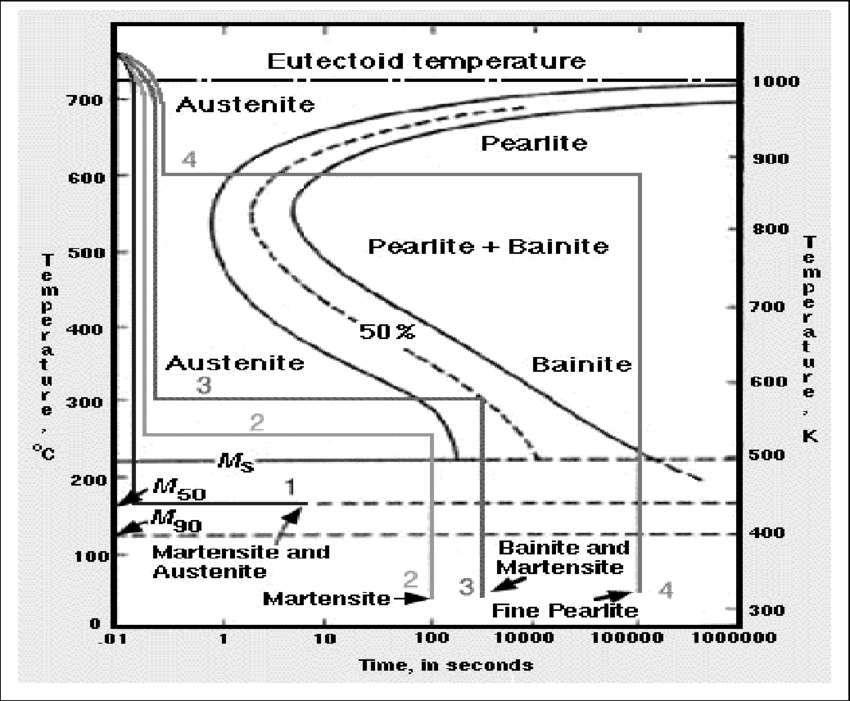

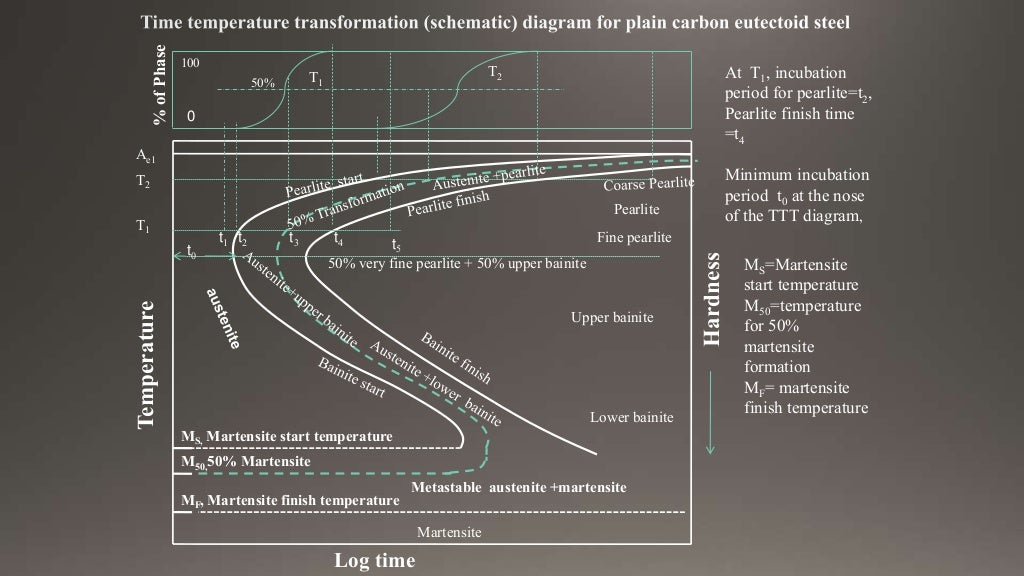

Diagram Ttt Time Temperature Transformation Pdf Transformation of austenite is plotted against temperature vs time on a logarithm scale to obtain the ttt diagram. the shape of diagram looks like either s or like c. at close to ae1 temperature, coarse pearlite forms at close to ae1 temperature due to low driving force or nucleation rate. Isothermal transformation diagrams (also known as time temperature transformation (ttt) diagrams) are plots of temperature versus time (usually on a logarithmic scale). they are generated from percentage transformation vs time measurements, and are useful for understanding the transformations of an alloy steel at elevated temperatures.

Solved A Ttt Time Temperature Transformation Diagram Is Shown Below Ttt diagram indicates when a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved. look at figure 1b and 1c. Question 4: answer the following questions related to the ttt (time temperature transformation) diagram drawn below for plain carbon steel of eutectoid composition: a) identify the final microstructure resulting from the cooling curve sketched below. T t t diagram is also called isothermal transformation diagram [temperature time –transformation]. it is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal [constant thermal] heat treatment of a previously austenitized alloy. There are number of methods. used to determine ttt diagrams. these are salt bath (figs. 12) techniques combined with metallography and hardness. thermodynamic predictions. salt bath technique combined. popular and accurate method to determine ttt diagram. heat treatment. salt bath for isothermal treatment. bath are used.

Temperature Time Transformation Diagram Ttt Diagram T t t diagram is also called isothermal transformation diagram [temperature time –transformation]. it is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal [constant thermal] heat treatment of a previously austenitized alloy. There are number of methods. used to determine ttt diagrams. these are salt bath (figs. 12) techniques combined with metallography and hardness. thermodynamic predictions. salt bath technique combined. popular and accurate method to determine ttt diagram. heat treatment. salt bath for isothermal treatment. bath are used. Temperature time transformation diagram (ttt), also known as isothermal transformation curves, are useful in planning heat treatments. the complete isothermal transformation diagram for an iron carbon alloy of eutectoid composition a (austenite), b (bainite), m (martensite), p (pearlite) is below:. Ttt diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. ttt diagram indicates a specific transformation starts and ends. Time temperature transformation (ttt) diagram is also known as isothermal transformation diagram, sigmoidal diagram, c curve, ors curve of the steel. it shows the time needed for austenite to begin to transform, to proceed halfway, and to be completely transformed at any constant temperature in the range covered by the curves. This diagram shows the time, at a particular temperature, to start to transform and finish transforming to a transformation product such as ferrite, pearlite or bainite. this diagram can be thought of as a map which plots the transformations of austenite as a function of constant temperature and time.

Time Temperature Transformation Diagram Ttt Diagram Temperature time transformation diagram (ttt), also known as isothermal transformation curves, are useful in planning heat treatments. the complete isothermal transformation diagram for an iron carbon alloy of eutectoid composition a (austenite), b (bainite), m (martensite), p (pearlite) is below:. Ttt diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. ttt diagram indicates a specific transformation starts and ends. Time temperature transformation (ttt) diagram is also known as isothermal transformation diagram, sigmoidal diagram, c curve, ors curve of the steel. it shows the time needed for austenite to begin to transform, to proceed halfway, and to be completely transformed at any constant temperature in the range covered by the curves. This diagram shows the time, at a particular temperature, to start to transform and finish transforming to a transformation product such as ferrite, pearlite or bainite. this diagram can be thought of as a map which plots the transformations of austenite as a function of constant temperature and time.