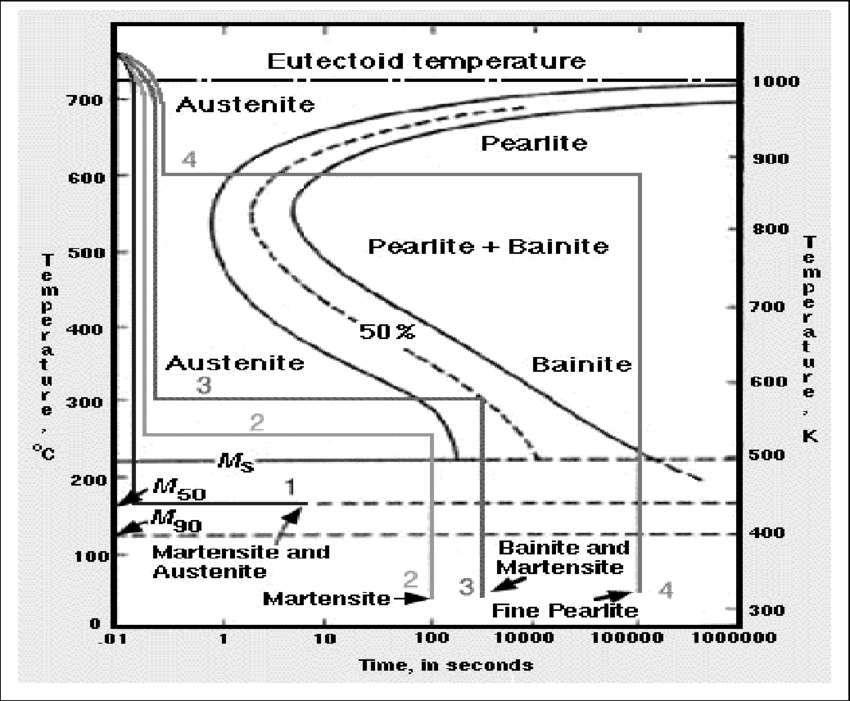

Solved A Ttt Time Temperature Transformation Diagram Is Shown Below Transformation of austenite is plotted against temperature vs time on a logarithm scale to obtain the ttt diagram. the shape of diagram looks like either s or like c. at close to ae1 temperature, coarse pearlite forms at close to ae1 temperature due to low driving force or nucleation rate. T t t diagram is also called isothermal transformation diagram [temperature time –transformation]. it is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal [constant thermal] heat treatment of a previously austenitized alloy.

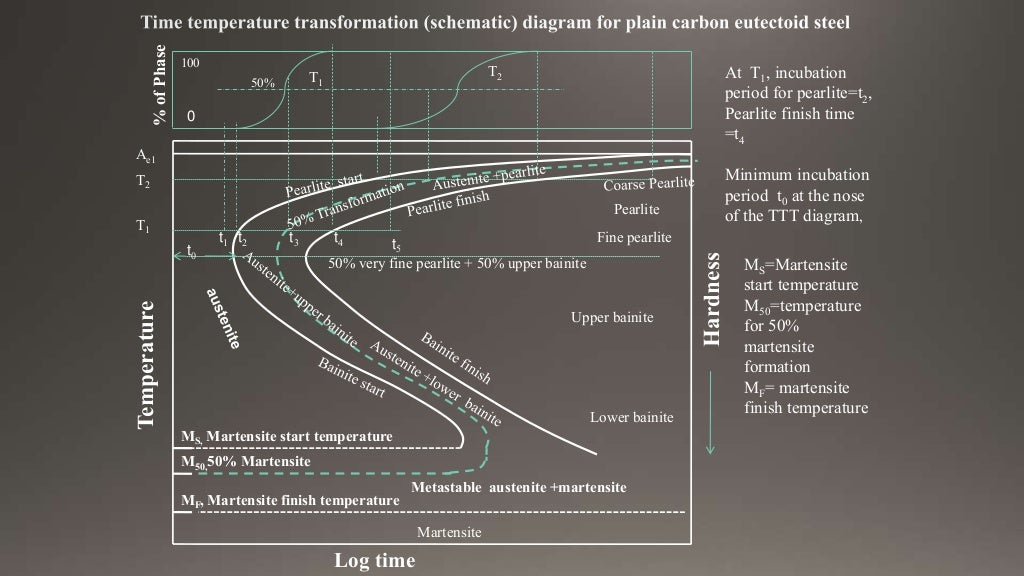

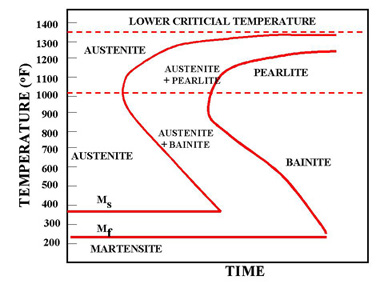

Temperature Time Transformation Diagram Ttt Diagram Ttt diagram indicates when a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved. look at figure 1b and 1c. Isothermal transformation diagrams (also known as time temperature transformation (ttt) diagrams) are plots of temperature versus time (usually on a logarithmic scale). they are generated from percentage transformation vs time measurements, and are useful for understanding the transformations of an alloy steel at elevated temperatures. Time temperature transformation (ttt) diagram is also known as isothermal transformation diagram, sigmoidal diagram, c curve, ors curve of the steel. it shows the time needed for austenite to begin to transform, to proceed halfway, and to be completely transformed at any constant temperature in the range covered by the curves. Transformation diagram (i t diagram, ttt diagram, or s curve) of the steel, shows the time required for austenite to begin to transform, to proceed halfway, and to be completely transformed at any constant temperature in the range covered by the curves. thus, the 1 t diagram of a steel may.

Time Temperature Transformation Diagram Ttt Diagram Time temperature transformation (ttt) diagram is also known as isothermal transformation diagram, sigmoidal diagram, c curve, ors curve of the steel. it shows the time needed for austenite to begin to transform, to proceed halfway, and to be completely transformed at any constant temperature in the range covered by the curves. Transformation diagram (i t diagram, ttt diagram, or s curve) of the steel, shows the time required for austenite to begin to transform, to proceed halfway, and to be completely transformed at any constant temperature in the range covered by the curves. thus, the 1 t diagram of a steel may. While transformation completes that time (t4 at t1) is called transformation finish, locus of that is called transformation finish line. therefore ttt diagram consists of different isopercentage lines of which 1%, 50% and 99% transformation lines are shown in the diagram. at high temperature while underlooling is low form coarse pearlite. To determine what will happen to an alloy as it cools under non equilibrium conditions, metallurgists use a time temperature transformation (ttt) curve. what is a ttt curve? a ttt curve plots the temperature on the y axis and the time on the x axis. the body of the graph consists of regions that represent different microstructures. Time temperature transformation (ttt ) diagram. t (time) t(temperature) t(transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. The diagrams that illustrate the transformation of austenite as a function of time at a constant temperature is a ttt, or isothermal transformation (it) diagram. in the simplest form (in plain carbon, or low alloy steels), these curves have a well defined ‘c’ or ‘s’ shape. each steel composition has its own different ‘s’ curve.

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies While transformation completes that time (t4 at t1) is called transformation finish, locus of that is called transformation finish line. therefore ttt diagram consists of different isopercentage lines of which 1%, 50% and 99% transformation lines are shown in the diagram. at high temperature while underlooling is low form coarse pearlite. To determine what will happen to an alloy as it cools under non equilibrium conditions, metallurgists use a time temperature transformation (ttt) curve. what is a ttt curve? a ttt curve plots the temperature on the y axis and the time on the x axis. the body of the graph consists of regions that represent different microstructures. Time temperature transformation (ttt ) diagram. t (time) t(temperature) t(transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. The diagrams that illustrate the transformation of austenite as a function of time at a constant temperature is a ttt, or isothermal transformation (it) diagram. in the simplest form (in plain carbon, or low alloy steels), these curves have a well defined ‘c’ or ‘s’ shape. each steel composition has its own different ‘s’ curve.

Solved Problem Points Time Temperature Transformation Chegg Time temperature transformation (ttt ) diagram. t (time) t(temperature) t(transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. The diagrams that illustrate the transformation of austenite as a function of time at a constant temperature is a ttt, or isothermal transformation (it) diagram. in the simplest form (in plain carbon, or low alloy steels), these curves have a well defined ‘c’ or ‘s’ shape. each steel composition has its own different ‘s’ curve.