Swing Check Valve Manufacturers Suppliers A swing check valve uses a hinged disc that swings open with forward flow and closes against reverse flow, preventing backflow. these valves operate automatically without power, are cost effective, are made of a wide range of materials, and have different designs for specific functionality. When should i use a swing check valve vs a spring check valve? use a swing check valve for low pressure systems and a spring check valve for high pressure, fast closing needs. view our online selection of check valves!.

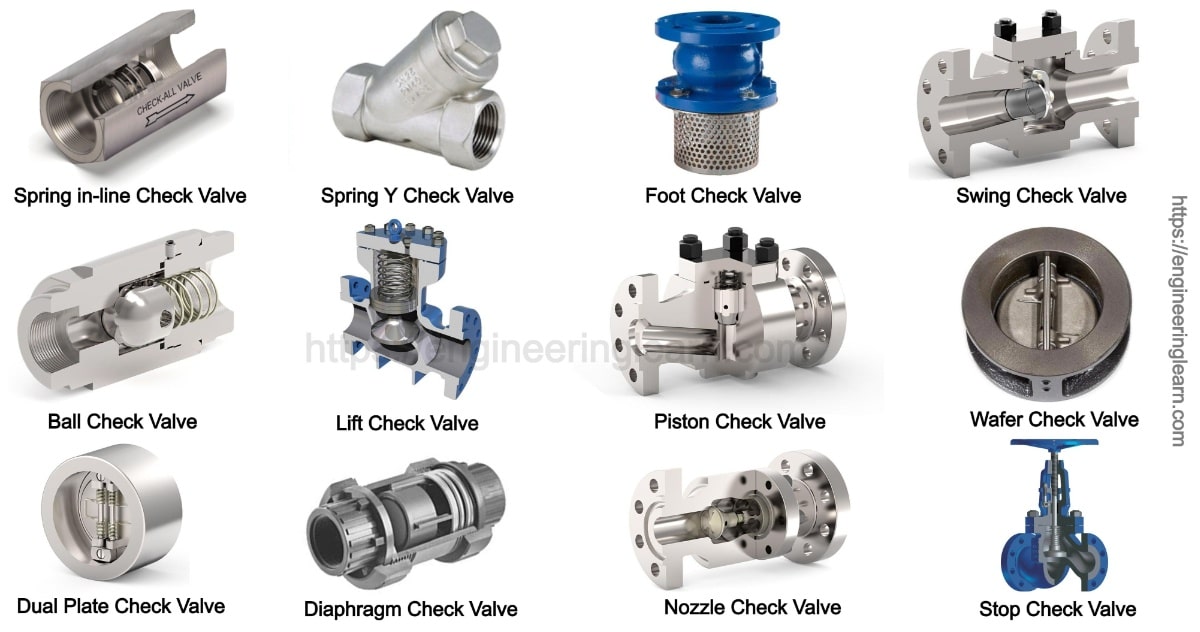

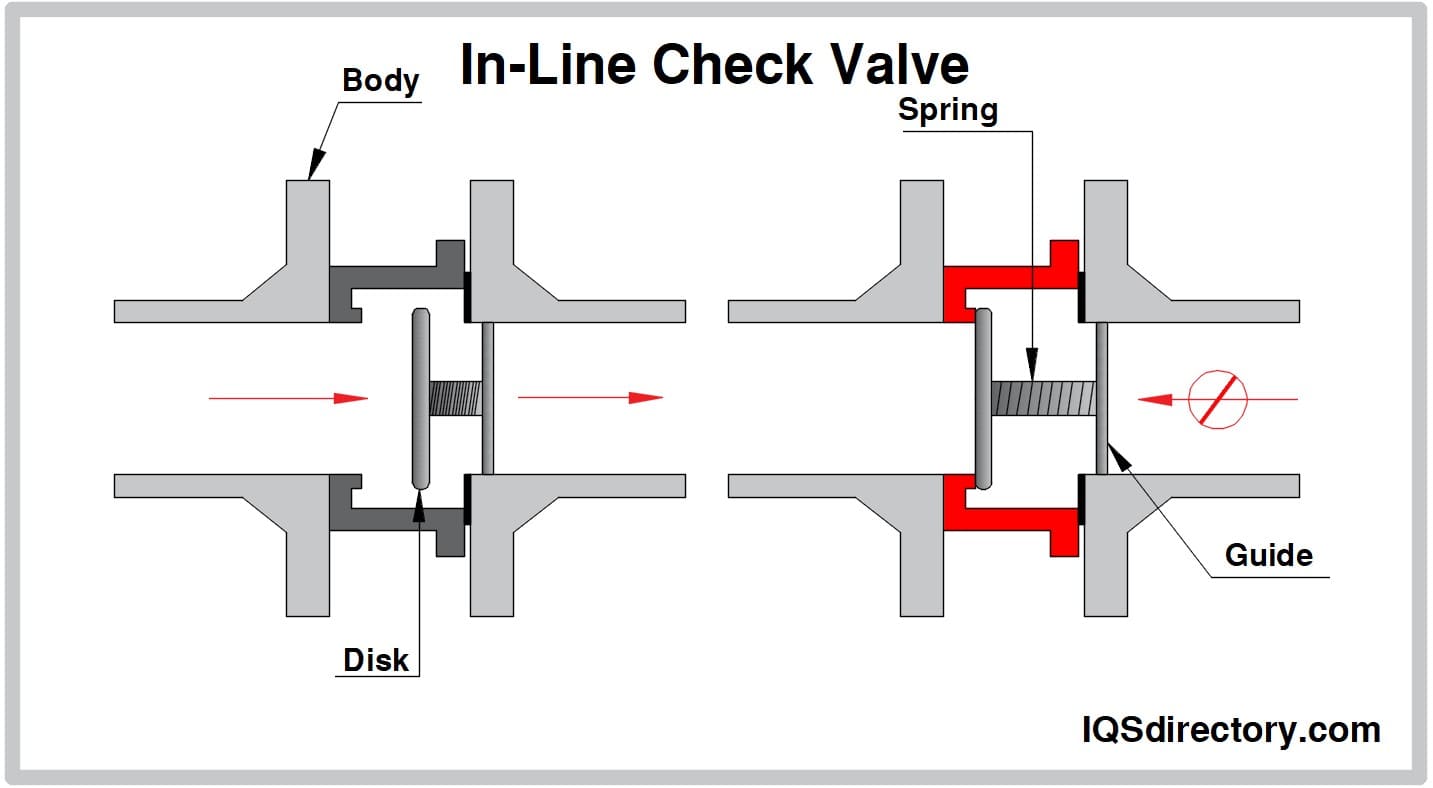

Swing Spring Check Valves Types Uses Features And 58 Off The lift check valve is coined from the “lift” motion it uses for allowing full open close capabilities in one direction as well as automatic backflow prevention. a piston or ball disc lifts or drops based on the pressure of flow. when flow enters, the pressure raises the disc into a lifted, open flow position, but when flow stops or reverses, gravity and the drop of pressure forces the. Spring check valves provide greater flexibility compared to swing check valves and are suitable for a range of applications, including both horizontal and vertical orientations. the spring mechanism maintains the disc in position during pressure drops, allowing for flow in any direction. The difference between swing check valves and spring check valves. the flapper in a swing check valve ‘swings’ off the seat to allow forward flow and then swings back onto the seat when the flow is stopped. in contrast, a spring loaded check valve incorporates a spring to assist in closing the check valve. learn more about spring check valves!. Among check valves, swing check valves and spring check valves are two of the most common types. each has unique features that impact performance, cost, and installation requirements. in this post, we’ll compare what is the difference between swing check and spring check.

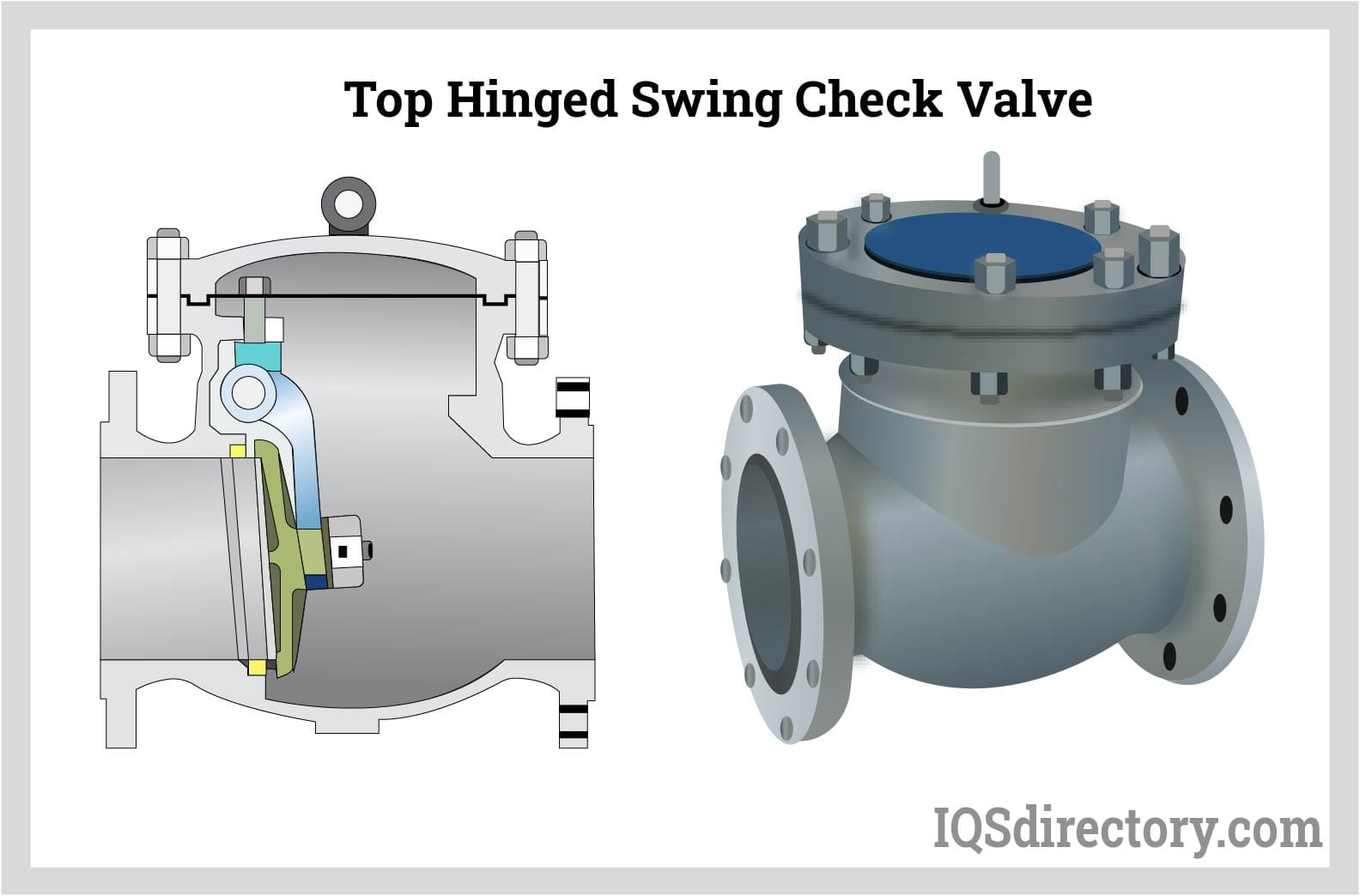

Swing Spring Check Valves Types Uses Features And 58 Off The difference between swing check valves and spring check valves. the flapper in a swing check valve ‘swings’ off the seat to allow forward flow and then swings back onto the seat when the flow is stopped. in contrast, a spring loaded check valve incorporates a spring to assist in closing the check valve. learn more about spring check valves!. Among check valves, swing check valves and spring check valves are two of the most common types. each has unique features that impact performance, cost, and installation requirements. in this post, we’ll compare what is the difference between swing check and spring check. Common swing check valve designs allow a main cover to be removed and all internals to be replaced without removing the valve body from the pipeline. there are several check valve closure methods to consider, from a simple lever and spring all the way to a complex hydraulic speed control. A swing check valve is a type of check valve that ensures fluid flows in only one direction, preventing backflow. it operates using a disc that swings on a hinge or shaft, opening when fluid flows in the desired direction and closing when flow reverses. A spring check valve is a valve that ensures unidirectional flow and prevents reverse flow. they have a single inlet and outlet and must have proper spring selection to perform effectively. on the side of a spring check valve, and all check valves, is an arrow that points in the flow direction. This post will compare swing check valves with other check valve types, examining their features, uses, and selection criteria. swing check valves. swing check valves are distinguished by a hinged disc that swings open to permit flow in one direction and shuts to stop backflow.