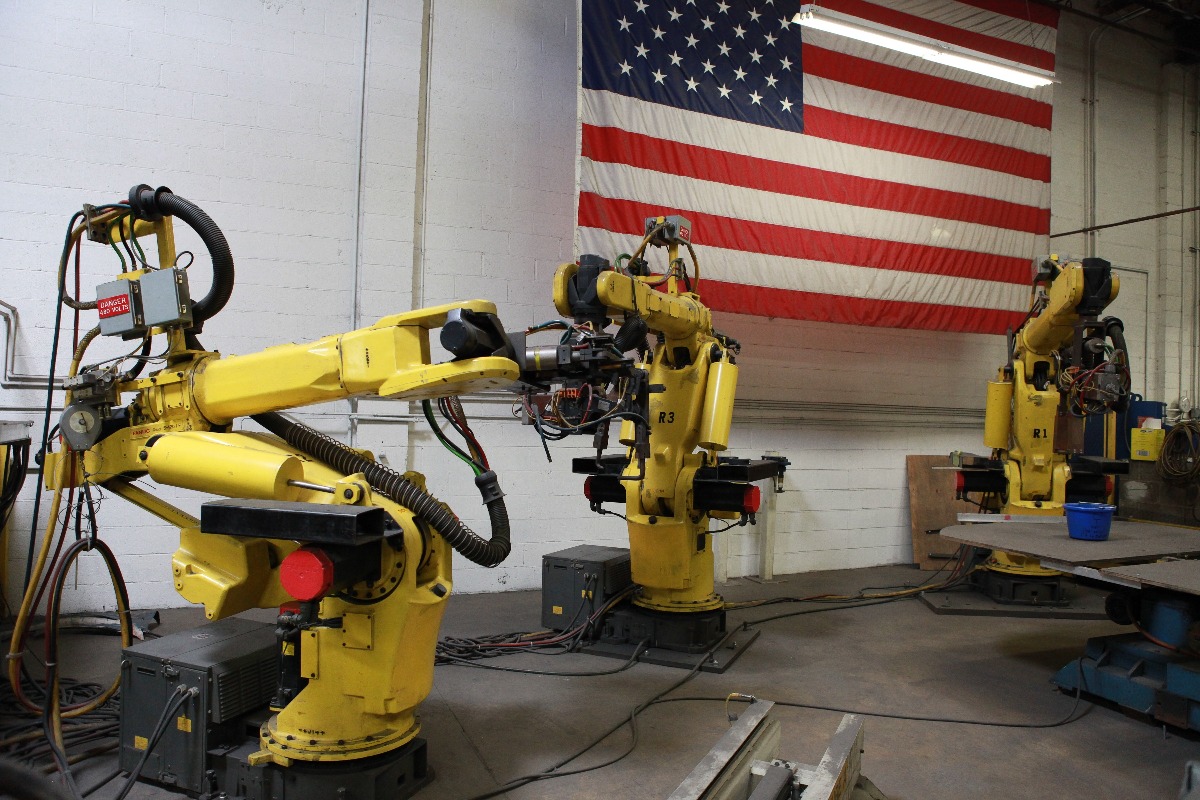

Technology Never Stops Evolving Strion Lasers Robotic Automation Welding System Weldingrobot

Premium Photo The Efficiency Of Industrial Automation Robotic Arms Here’s a look at strion laser’s robotic automation welding system in action — welding aluminum bicycle components with precision and efficiency. ⚡️🔹 faster. Strion laser recently completed a successful application case of automated robotic laser welding for saddle port thin tubes — a process requiring exceptional precision and thermal control.

5 Automation Trends Impacting Robotic Welding Systems And Processes The developed system consists of three steps: robotic arm alignment with the detected endpoint, laser scan for increasing accuracy for welding, and automated robotic welding. Robotic laser welding works by combining the precision of lasers with the versatility of robotic systems, creating a highly accurate and effective procedure. the process begins with a laser source, a high powered fiber laser or co2 laser, that generates an intense, focused beam of light. Advancements in welding technology have resulted in significant breakthroughs that have revolutionized a variety of industries. a game changer among these advancements, laser welding robots are characterized by their unparalleled precision and efficiency. Ai driven welding systems, robotic automation, and remote welding solutions are reducing costs, improving efficiency, and ensuring greater precision. for industries looking to stay ahead in the competitive market, adopting these smart welding technologies will be essential.

Premium Ai Image A New Era Of Automation The Integration Of Robotic Advancements in welding technology have resulted in significant breakthroughs that have revolutionized a variety of industries. a game changer among these advancements, laser welding robots are characterized by their unparalleled precision and efficiency. Ai driven welding systems, robotic automation, and remote welding solutions are reducing costs, improving efficiency, and ensuring greater precision. for industries looking to stay ahead in the competitive market, adopting these smart welding technologies will be essential. The fusion of robotic automation with laser welding technology has revolutionized the production processes across industries. this advanced method offers unparalleled accuracy and speed, ensuring impeccable welds on various materials with minimal heat distortion. From intelligent control systems that provide real time data analysis to robots that execute intricate welding tasks with unmatched precision, the landscape of laser welding is rapidly evolving. how do these advancements translate to enhanced production efficiency and product quality?. 【our advantages】 ⚙ self repairing power, 5000 hours without attenuation👨🏭 integration design, one stop service 🏭 own laser source with intellectual pr. As a niche subfield within the broader welding industry, there can be some mystery surrounding laser welding and how to automate it. understanding the suppliers and components of a robotic laser welding system is critical for beginning your automation journey.

The High Technology Laser Welding Robot By Robotic System Stock Image The fusion of robotic automation with laser welding technology has revolutionized the production processes across industries. this advanced method offers unparalleled accuracy and speed, ensuring impeccable welds on various materials with minimal heat distortion. From intelligent control systems that provide real time data analysis to robots that execute intricate welding tasks with unmatched precision, the landscape of laser welding is rapidly evolving. how do these advancements translate to enhanced production efficiency and product quality?. 【our advantages】 ⚙ self repairing power, 5000 hours without attenuation👨🏭 integration design, one stop service 🏭 own laser source with intellectual pr. As a niche subfield within the broader welding industry, there can be some mystery surrounding laser welding and how to automate it. understanding the suppliers and components of a robotic laser welding system is critical for beginning your automation journey.

Comments are closed.