Types Of Check Valves Pdf Swing, tilting disk, dual plate, non slam and stop check are the general forms of check valves. the classification of the check valve can be decided by the types of discs used; these are: • swing check valve 1. top hinged disc. 2. tilting disc. • lift check valve 1. piston type 2. Describe the various types of check valves and discuss the common selection criteria such as cost and fluid compatibility, which can be used to narrow down the field of selection. finally, the check valves will be rated on every criteria so that a methodical decision process can be.

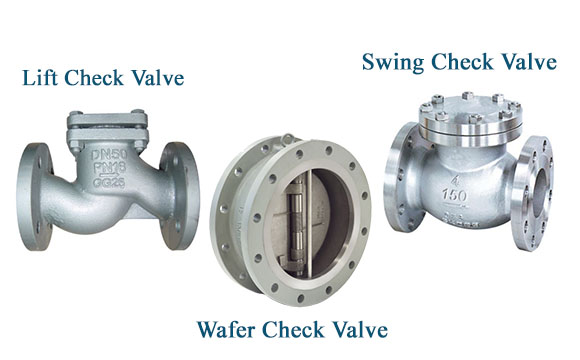

Types Of Check Valves Jonloo Valve Company These valve types can withstand both high and low pressure situations. check valves are available in both vertical and horizontal models. the three different kinds of check valves. lift check valve; piston check valve; swing check valve. #1 lift check valve. this valve uses a disc, piston, or ball as a checking mechanism. Check valves are essential components in fluid systems, allowing flow in one direction while preventing reverse flow. these valves are typically found in pipelines, pumps, and other fluid handling equipment. they come in different shapes, sizes, and materials, each with unique features and applications. The purpose of a check valve in an application will determine some design parameters. generally, check valve functions can be divided into three categories: non return, vent, and fill and drain. it is important to select the correct check valve to ensure proper functionality during system operation. non return check valve. All check valves are flow sensitive and rely on fluid pressure to open and use internal spring hinge force to close. check valves come in various types depending on construction and application, including swing check, lift check, tilting disc check, ball check, axial flow check, stop check and poppet check. selection and sizing .

Types And Application Of Check Valves Saba Dejlah The purpose of a check valve in an application will determine some design parameters. generally, check valve functions can be divided into three categories: non return, vent, and fill and drain. it is important to select the correct check valve to ensure proper functionality during system operation. non return check valve. All check valves are flow sensitive and rely on fluid pressure to open and use internal spring hinge force to close. check valves come in various types depending on construction and application, including swing check, lift check, tilting disc check, ball check, axial flow check, stop check and poppet check. selection and sizing . In short, swing check valves de pend upon reversal of flow to close. silent, spring loaded check valves are designed so that the disc returns to its seat at zero velocity before the reversal of flow occurs. table 1 — types of check valves there are several basic types of conventional silent check valves: figure 5 figure 6 figure 7 1. 2. 3. 4. Check valves are poppet style elements that allow free flow in one direction while preventing flow in the reverse direction. they can be used to isolate portions of a hydraulic circuit or to provide a free flow path around a restrictive valve. • examples of the common types are the globe valve, gate valve, ball valve, plug valve, butterfly valve, diaphragm valve, check valve, pinch valve, and safety valve. • each type of valve has been designed to meet specific needs. some valves are capable of throttling flow, other valve types can. 1. swing check valve types et 000l10.1ex & et 000l10.2ex 1.1 application swing check valves are self acting valves preventing the back flow of the fluid. it is used especially in power engineering, chemical industry as well as other industries depending on material selection. swing check valves are not shut off valves. 1.2 technical description.