Types Of Copper In Pcb Design

Copper Pcb Manufacturing Design Copper Pcb Manufacturing Full Services This article examines how to select pcb copper foils for a high frequency pcb layout and which materials are most important. Explore everything about copper pcb boards, from raw materials to different types and their applications. learn how these boards are fundamental in electronics manufacturing.

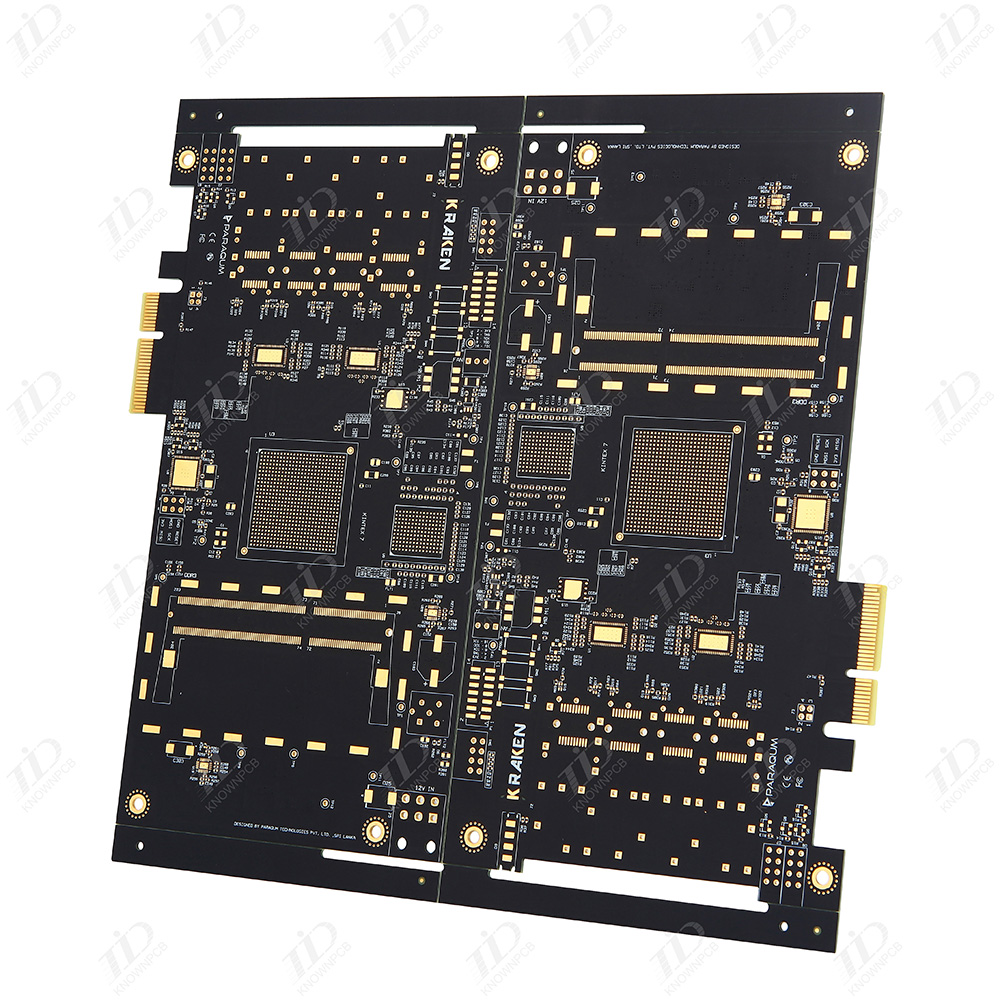

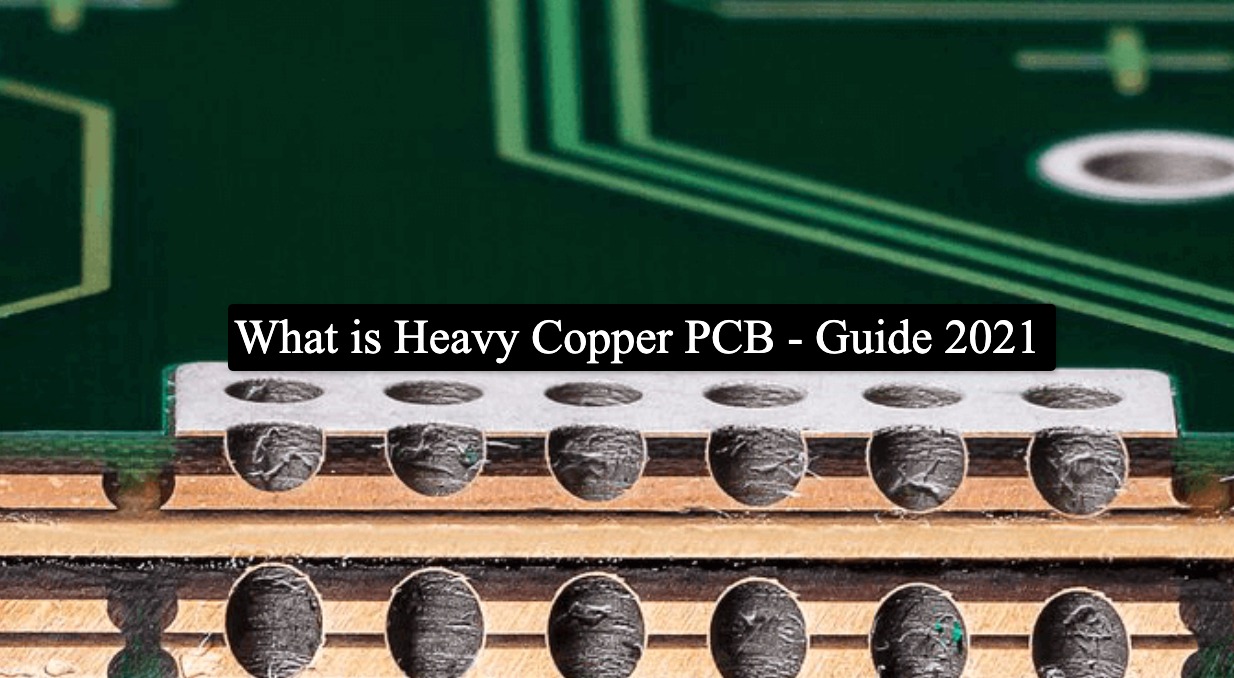

Heavy Copper Pcb Design Absolute Electronics Services In this article, we will explore the various types of pcb finishing copper, discuss copper thickness standards like outer finish cu 1oz and inner base cu hoz, and explain their significance in pcb functionality. Electro deposited copper is typically used in rigid pcbs. rolled copper: a type of copper, made very thin by processing between heavy rollers, extensively used to produce flexible and high speed boards. Two types of copper foils are typically used in manufacturing pcbs: electrodeposited (ed) and rolled annealed (ra) copper. the ra copper fabrication process starts by passing pure copper ingots through a series of rolling processes, resulting in the desired thickness of copper foil. Why do we use different types of copper in pcb design? and what is the relationship between the type of copper and copper roughness? tech consultant zach peterson dives into these.

Heavy Copper Pcb Design Guidelines For Manufacturing Two types of copper foils are typically used in manufacturing pcbs: electrodeposited (ed) and rolled annealed (ra) copper. the ra copper fabrication process starts by passing pure copper ingots through a series of rolling processes, resulting in the desired thickness of copper foil. Why do we use different types of copper in pcb design? and what is the relationship between the type of copper and copper roughness? tech consultant zach peterson dives into these. What are copper clad laminates? copper clad laminates (ccl) are critical materials used in the fabrication of printed circuit boards. consisting of an insulating base material and copper foil, they form the foundational layers onto which circuitry is etched. Let’s explore the role of copper in pcb boards and how it enables functional, long lasting, and efficient circuits. before diving into the specifics of copper pcbs, let’s briefly overview the pcb fabrication process: pcb design – all trace routing and board dimensions are virtually designed. Explore the various types of copper based pcbs, their unique properties, advantages, and applications in modern electronics. learn how they enhance performance and reliability in diverse industries. In this guide, we’ll explain what copper based pcbs are, their different types, and why they’re used in things like led lights, cars, and medical tools. we’ll also look at their pros and cons, how they compare to aluminum pcbs, and when it makes sense to use them. what is a copper based pcb?.

Comments are closed.