What Are Ipc S Requirements For Copper Wrap Plating In Through Hole Copper wrap plating structures. the ipc 6021b standard has included a copper wrap plating requirement for via in pad structures. the filled copper plating should continue around the edge of the via hole and extend onto the annular ring surrounding the via pad. Ipc technical question of the week: what are ipc's requirements for copper wrap plating in through hole vias?.

Ipc Plating Specifications Pdf Printed Circuit Board Standard Ipc has released new plating requirements to allow for finer line widths. table 3 10 now requires only 5µm [197 µin] minimum wrap plating for buried vias > 2 layers, through holes, and blind vias. prior to this revision, the minimum wrap plating requirement was 12 µm [472 µin]. Ipc 6012b specifies that copper wrap plating shall be continuous from the filled plated hole onto the external surface of the plated structure and extend by a minimum of 25 microns (984 micro inches) where an annular ring is required. figure 1 shows this requirement. The ipc specification for class 2 requires a minimum of 0.000197 inch continuous copper wrap from hole wall onto the external surface of a plated structure, and ipc class 3 requires a minimum of 0.000472 inch continuous copper wrap. 0.1 scope this addendum provides requirements to be used in addition to, and in some cases, in place of, those published in ipc 6012f to ensure the reliability of printed boards that must survive the vibration, ground testing, and thermal cycling environments of space and military avionics.

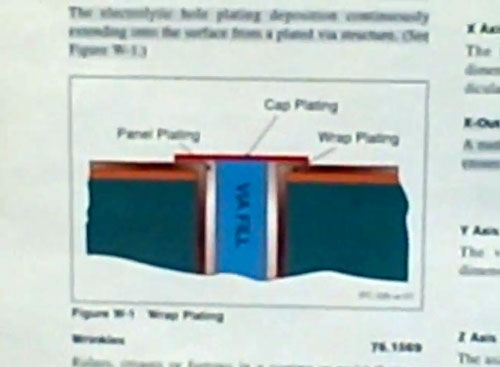

Pcb Interconnection Options Plated Through Hole Vs Vias Victory The ipc specification for class 2 requires a minimum of 0.000197 inch continuous copper wrap from hole wall onto the external surface of a plated structure, and ipc class 3 requires a minimum of 0.000472 inch continuous copper wrap. 0.1 scope this addendum provides requirements to be used in addition to, and in some cases, in place of, those published in ipc 6012f to ensure the reliability of printed boards that must survive the vibration, ground testing, and thermal cycling environments of space and military avionics. Incorporate at least 1 mil of copper plating inside the holes to ensure reliability. keep the via protrusion more than 1.96 mil and cap plating of a minimum of 0.472 mil. set external and internal annular ring dimensions as 2 mil and 1 mil respectively. In terms of wrap plating requirements for via in pad structures, ipc 6012b states that wrap plating is required for all vias that are in contact with a surface mount pad or hole pad. This paper discussesa through hole copper filling process for application to high density interconnects constructions and ic substrates. the process consists two acid copper plating cycles. In ipc standard revisions such as ipc 6012b and 6012e, the requirements of copper wrap plating and wrap plating thickness are specified for all filled plated through holes. the standard classifies electronics designs as class 1 for general electronic products, class 2 for dedicated service electronic products, and class 3 for high reliability.

Pcb Interconnection Options Plated Through Hole Vs Vias Victory Incorporate at least 1 mil of copper plating inside the holes to ensure reliability. keep the via protrusion more than 1.96 mil and cap plating of a minimum of 0.472 mil. set external and internal annular ring dimensions as 2 mil and 1 mil respectively. In terms of wrap plating requirements for via in pad structures, ipc 6012b states that wrap plating is required for all vias that are in contact with a surface mount pad or hole pad. This paper discussesa through hole copper filling process for application to high density interconnects constructions and ic substrates. the process consists two acid copper plating cycles. In ipc standard revisions such as ipc 6012b and 6012e, the requirements of copper wrap plating and wrap plating thickness are specified for all filled plated through holes. the standard classifies electronics designs as class 1 for general electronic products, class 2 for dedicated service electronic products, and class 3 for high reliability.

Engineering And Hobby Thru Hole Copper Plating This paper discussesa through hole copper filling process for application to high density interconnects constructions and ic substrates. the process consists two acid copper plating cycles. In ipc standard revisions such as ipc 6012b and 6012e, the requirements of copper wrap plating and wrap plating thickness are specified for all filled plated through holes. the standard classifies electronics designs as class 1 for general electronic products, class 2 for dedicated service electronic products, and class 3 for high reliability.