Additive Versus Subtractive Manufacturing Pdf Computer Aided Design By mr. ali hosseini(founder & ceo, senra)from the 'anatomy and adoption of smart manufacturing' round table conference. watch full video here : y. Additive manufacturing vs subtractive manufacturing: what are their differences? additive manufacturing processes build products by adding materials layer by layer, while subtractive manufacturing removes parts of a solid material to create the product parts.

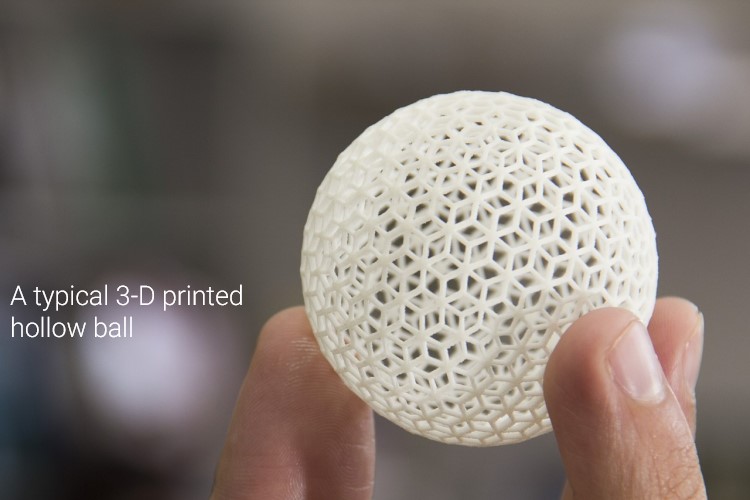

Difference Between Additive And Subtractive Manufacturing Additive and subtractive manufacturing each offer unique advantages that cater to different needs in the manufacturing industry. understanding the strengths and limitations of both methods will help you make informed decisions about which process to use for your specific application. Additive and subtractive manufacturing are two approaches to producing parts and products. additive manufacturing creates final products by adding material layer by layer, while subtractive manufacturing involves removing material from a larger piece to make the final product. Additive manufacturing (am) and subtractive manufacturing (sm) differ fundamentally in their approaches: am builds objects layer by layer, adding material only where needed, which minimizes waste and allows for complex geometries and customization. Additive manufacturing is a process that adds successive layers of material to create an object, often referred to as 3d printing. subtractive manufacturing, as the name suggests, is the opposite. rather than adding layers, subtractive manufacturing involves removing sections of a material by machining or cutting it away.

Difference Between Additive And Subtractive Manufacturing Additive manufacturing (am) and subtractive manufacturing (sm) differ fundamentally in their approaches: am builds objects layer by layer, adding material only where needed, which minimizes waste and allows for complex geometries and customization. Additive manufacturing is a process that adds successive layers of material to create an object, often referred to as 3d printing. subtractive manufacturing, as the name suggests, is the opposite. rather than adding layers, subtractive manufacturing involves removing sections of a material by machining or cutting it away. Additive processes are suitable for a narrow range of materials. subtractive processes pose no restriction on working material. it is suitable for small size components. it cannot accommodate large components. it can process small to large objects. any complex shape can be directly produced by these processes. Additive vs subtractive manufacturing: what’s the difference? in additive manufacturing, material is added layer by layer, while subtractive manufacturing removes material. subtractive processes are often faster and more precise but less flexible for complex designs. In real time manufacturing, subtractive and additive manufacturing processes are a duo that complement each other; while additive processes give versatility, subtractive supplies strength. for most products that you see, some additive and subtractive procedures were likely employed to complete them. Learn the key differences between additive and subtractive manufacturing processes. understand the benefits and limitations of each approach to help you choose the best option for your project, whether for prototyping, production, or custom parts.

What S The Difference Between Additive And Subtractive Manufacturing Additive processes are suitable for a narrow range of materials. subtractive processes pose no restriction on working material. it is suitable for small size components. it cannot accommodate large components. it can process small to large objects. any complex shape can be directly produced by these processes. Additive vs subtractive manufacturing: what’s the difference? in additive manufacturing, material is added layer by layer, while subtractive manufacturing removes material. subtractive processes are often faster and more precise but less flexible for complex designs. In real time manufacturing, subtractive and additive manufacturing processes are a duo that complement each other; while additive processes give versatility, subtractive supplies strength. for most products that you see, some additive and subtractive procedures were likely employed to complete them. Learn the key differences between additive and subtractive manufacturing processes. understand the benefits and limitations of each approach to help you choose the best option for your project, whether for prototyping, production, or custom parts.